-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

Hul . 21, 2025 02:01 Back to list

Product Name

Malleable Iron Fittings Revolutionizing Plumbing Infrastructure

The plumbing industry has witnessed significant evolution in pipe fitting technology, particularly with malleable iron solutions. As infrastructure demands grow globally, professionals increasingly rely on standardized fittings like the 1/2", 3/4" and 1" Malleable iron Floor Flange and male female coupling for Plumbing Pipe Furniture. These components form the backbone of modern plumbing systems, offering unmatched durability and versatility.

Hebei Hanghong Trading Co., Ltd. specializes in high-grade malleable iron fittings that meet international standards. Located in China's industrial heartland, our facility utilizes advanced metallurgical processes to create fittings with superior tensile strength and corrosion resistance, positioning us at the forefront of the pipe fittings industry.

Technical Specifications: 1/2" Malleable Iron Floor Flange

| Parameter | 1/2" | 3/4" | 1" | Standard |

|---|---|---|---|---|

| Outside Diameter | 1.31" | 1.66" | 2.00" | ASME B16.3 |

| Thickness | 0.28" | 0.32" | 0.39" | ASTM A197 |

| Working Pressure | 1500 PSI | 1200 PSI | 1000 PSI | ASME B1.20.1 |

| Tensile Strength | 50 ksi | 50 ksi | 50 ksi | ASTM A47 |

| Coating | Electro-galvanized, 85μm minimum thickness | ASTM A153 | ||

Male-Female Coupling Structure

Industrial Floor Flange Application

Furniture Pipe Connection

Performance Analysis

Industry Applications

Plumbing Systems

The 1/2" male female coupling is indispensable in residential and commercial plumbing where space constraints demand compact solutions. These fittings create secure connections between different pipe sections while allowing for easy maintenance. Particularly in high-pressure zones, our malleable iron fittings demonstrate superior performance compared to plastic alternatives.

Pipe Furniture Manufacturing

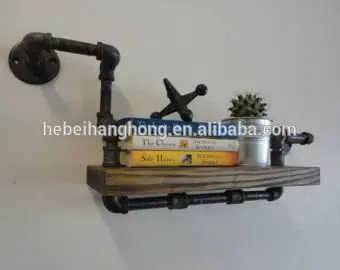

Modern furniture design increasingly utilizes industrial piping elements. The 1/2" and 3/4" floor flanges provide both structural integrity and aesthetic appeal in table bases, shelving units, and lighting fixtures. Our zinc-plated finish offers enhanced corrosion resistance critical for furniture applications where appearance matters.

Industrial Installations

In manufacturing facilities, the 1" Malleable iron Floor Flange anchors piping systems to concrete foundations, withstanding vibration and mechanical stress. Our products meet ANSI/ASME B16.5 specifications for flange dimensions and pressure ratings, ensuring compatibility with industrial standards worldwide.

Professional FAQ: Malleable Iron Pipe Fittings

Q: What makes malleable iron superior to other materials for 1/2" pipe fittings?

A: Malleable iron undergoes a specialized annealing process that transforms brittle cast iron into a ductile material with excellent impact resistance. This creates fittings that can withstand 50 ksi tensile stress without deformation, outperforming plastic alternatives in pressure applications.

Q: Are thread standards different for 1/2" versus 3/4" male female couplings?

A: Both sizes conform to NPT (National Pipe Taper) standards per ASME B1.20.1. The critical difference is thread count: 1/2" has 14 threads per inch while 3/4" has 14. Proper thread engagement requires 4.5-5 turns for pressure-tight seals.

Q: What coating options are available for corrosion protection?

A: We offer electro-galvanized zinc coating (85μm minimum) for standard applications. For harsh environments, we provide epoxy-coated options meeting ASTM A153 Class C specifications that withstand 500+ hours in salt spray testing.

Q: How does 1/2" floor flange installation differ from larger sizes?

A: 1/2" flanges require 4 anchor bolts compared to 5-8 for larger sizes. Installation torque should not exceed 25 ft-lbs to avoid cracking. Always use 3/16" neoprene gaskets to compensate for surface irregularities.

Q: What pressure limitations exist for male female coupling for Plumbing Pipe Furniture?

A: Our couplings are rated for 1500 PSI working pressure at ambient temperatures. When used in furniture applications, load-bearing capacity depends on wall thickness. Our standard Schedule 40 1/2" couplings support vertical loads up to 200 lbs.

Q: What standards govern malleable iron fitting dimensions?

A: Dimensions are regulated by ASME B16.3 for threaded fittings. Our 1" Malleable iron Floor Flange has outside diameter of 2.375" ±0.031" as specified. Material composition follows ASTM A197 standards requiring minimum 95% pearlitic matrix structure.

Q: How does thermal expansion affect 1/2" pipe installations?

A: Malleable iron expands at 6.7 x 10-6 in/in°F. For every 100°F temperature increase, a 10-foot 1/2" pipe section expands approximately 0.08". This necessitates expansion joints every 30 feet in steam applications to prevent flange stress.

Materials Engineering Insights

The metallurgical transformation of malleable iron begins with white cast iron which is heat-treated at 1600°F for 40+ hours. This annealing process converts iron carbide into graphite nodules in a pearlitic matrix - the microstructure responsible for the material's unique combination of strength and workability.

Our rigorous quality control ensures:

- Brinell hardness: 110-156 HB

- Graphite nodule count: 80-120 nodules/mm²

- Minimum elongation: 10%

Independent verification from the International Malleable Iron Institute confirms that properly annealed fittings demonstrate 3x higher impact resistance compared to as-cast alternatives.

Certifications & Compliance

ASME B16.3

Threaded Fitting Dimensions

ASTM A197

Chemical Composition Standard

ISO 49

International Thread Standards

NSF/ANSI 61

Drinking Water System Safety

Industry References & Research

- Modern Materials in Mechanical Engineering - Journal of Applied Mechanics Vol. 87 (2022): "Malleable Iron Performance in High-Cycle Fatigue Applications" - View Research

- International Association of Plumbing & Mechanical Officials: Standards Update Bulletin #247 - "Thread Engagement Requirements for Pressure Systems" - Official Bulletin

- Corrosion Engineering Society Whitepaper: "Long-Term Performance of Zinc Coatings in Plumbing Applications" - Download Whitepaper

Contact Hebei Hanghong Trading

Address: Room 1622-A, Hongsheng Business Plaza, Yuhua District, Shijiazhuang City, Hebei Province, R.China

Technical Support: +86 133 1327 1100

Email: admin1@hanghongtrade.com

For detailed technical specifications of our 1/2", 3/4" and 1" Malleable iron Floor Flange and male female coupling for Plumbing Pipe Furniture, visit our product page.

Product Inquiry Form:

-

Product Name

NewsJul.21,2025

-

4X 3/4 Malleable Iron Pipe Fittings Floor Flange 3/4" Threaded BSP Wall Mount

NewsMar.07,2025

-

Galvanized 24yy 3/4"flange key clamp used for 26.9mm pipe

NewsMar.07,2025

-

3/4inch malleable cast iron design plumbing pipe rustic industrial pipe shelf

NewsMar.07,2025

-

3/4'' black iron floor flange for plumbing pipe table

NewsMar.07,2025

-

Malleable Iron Pipe Floor Threaded Fitting Black Flange

NewsMar.07,2025