-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

აგვ . 17, 2025 02:40 Back to list

1/2" Malleable Iron Pipe Fittings for Furniture & Plumbing

Navigating the Landscape of Industrial Pipe Fittings: The Enduring Value of Malleable Iron

In the intricate world of industrial plumbing, infrastructure, and bespoke design, the integrity and reliability of every component are paramount. Among the foundational elements that have stood the test of time, malleable iron fittings, particularly the 1/2" Malleable Iron Floor Flange, continue to play a pivotal role. These fittings are not merely connectors; they are critical enablers of robust systems, from complex petrochemical pipelines to aesthetic plumbing pipe furniture. The industry currently sees a blend of traditional durability with demands for enhanced performance, sustainability, and aesthetic versatility. Trends indicate a growing appreciation for materials offering exceptional strength-to-weight ratios and ease of installation, alongside a drive for components that meet stringent international standards for environmental compliance and operational safety. Manufacturers are increasingly focusing on precision engineering and advanced surface treatments to extend product lifespan and broaden application scopes, ensuring that essential components like the 1/2" floor flange remain at the forefront of innovation while upholding their legacy of reliability.

The demand for robust and adaptable pipe components has spurred innovations in material science and manufacturing processes, yet the inherent properties of malleable iron — its ductility, high tensile strength, and excellent machinability — ensure its continued relevance. For B2B decision-makers and technical personnel, understanding the nuances of these fittings, from the common 1/2" size to larger 3/4" and 1" variants, is essential for optimizing system performance and project longevity. This extends beyond merely connecting pipes; it encompasses ensuring leak-proof seals, accommodating thermal expansion, and providing stable structural support in diverse environments. The increasing adoption of these fittings in non-traditional sectors, such as the burgeoning market for industrial-style furniture, highlights their intrinsic versatility and aesthetic appeal, reinforcing their market position. Moreover, the focus on supply chain resilience and quality assurance has never been higher, compelling manufacturers to invest in cutting-edge production technologies and rigorous testing protocols. This commitment guarantees that every malleable iron fitting, regardless of size or application, delivers consistent, dependable performance that project engineers and designers can rely upon implicitly.

Furthermore, the industry is witnessing a significant shift towards product customization and specialized solutions, driven by unique project requirements in sectors ranging from bespoke architectural design to high-pressure fluid conveyance. This includes requests for specific finishes, non-standard threading, or unique structural forms that deviate from conventional designs. Manufacturers capable of offering these tailor-made solutions, alongside their standard offerings of 1/2", 3/4", and 1" Malleable Iron Floor Flange, and male female coupling for Plumbing Pipe Furniture, are gaining a competitive edge. This adaptability, combined with a commitment to stringent quality control, positions malleable iron fittings as a reliable choice for long-term investments. The emphasis on robust materials and precise manufacturing processes ensures that these components can withstand demanding operational conditions, including variations in temperature, pressure, and corrosive environments, without compromising structural integrity or sealing effectiveness. This holistic approach to product development and market responsiveness is critical in meeting the evolving demands of industrial and decorative applications globally, reaffirming the indispensable nature of high-quality malleable iron pipe fittings in the modern age.

The Core of Quality: Decoding the Manufacturing Process of a 1/2" Malleable Iron Floor Flange

The production of a high-quality 1/2" Malleable Iron Floor Flange is a meticulous process, integrating advanced metallurgical science with precise engineering techniques. It begins with the selection of raw materials: high-grade pig iron, known for its excellent castability, combined with specific percentages of carbon, silicon, manganese, sulfur, and phosphorus. This precise chemical composition is crucial for achieving the desired properties during the subsequent heat treatment. The journey typically commences with sand casting, where molten white cast iron, rich in carbon in a combined form, is poured into intricately designed molds. These molds are crafted to ensure dimensional accuracy and a smooth surface finish, minimizing the need for extensive post-casting remediation. The design of the pattern accounts for shrinkage during cooling, a critical factor in producing parts that meet stringent dimensional tolerances, especially for standardized components like the 1/2" floor flange.

Following casting, the most distinctive step is the malleabilizing heat treatment. This annealing process transforms the brittle white cast iron into ductile malleable iron. The castings are heated in specialized furnaces to temperatures ranging from 850°C to 950°C (1560°F to 1740°F) for extended periods, sometimes up to 100 hours, followed by controlled cooling. This process causes the iron carbides to decompose into graphite nodules (temper carbon) and ferrite, imparting the material with enhanced ductility, toughness, and machinability without significant loss of strength. This transformation is what differentiates malleable iron from other cast irons, making it ideal for applications requiring impact resistance and formability, such as pipe fittings. After malleabilizing, the flanges undergo precision machining. This critical stage involves CNC (Computer Numerical Control) machining to create accurate NPT (National Pipe Taper) or BSP (British Standard Pipe) threads, precise bolt holes, and a flat mounting surface. CNC ensures consistent thread quality, crucial for leak-proof connections and ease of installation in plumbing pipe furniture and industrial systems.

Quality control is integrated throughout the entire manufacturing process, from raw material inspection to final product verification. This includes spectral analysis of molten iron to verify chemical composition, microscopic examination of samples to assess graphite nodule formation, and mechanical testing for tensile strength, elongation, and hardness. Each 1/2" floor flange, along with its 3/4" and 1" counterparts and various male female couplings, undergoes rigorous dimensional checks using precision gauges and thread gauges to ensure compliance with standards like ANSI B1.20.1 for pipe threads and ISO 49:1983 for dimensions. Hydrostatic testing is performed to verify pressure integrity, ensuring that the fittings can withstand specified working pressures without leakage. Furthermore, products are often subjected to surface treatments, such as hot-dip galvanizing or black iron oxide coating, to enhance corrosion resistance and aesthetic appeal, extending their service life in various applicable industries like petrochemical, metallurgy, and water supply/drainage systems. These stringent quality measures ensure that the finished products offer superior durability, long service life, and consistent performance, contributing to energy efficiency by preventing leaks and reducing system maintenance in demanding environments.

Technical Specifications and Performance Parameters: The 1/2" Malleable Iron Floor Flange

For engineers, procurement specialists, and project managers, understanding the precise technical specifications of components like the 1/2" Malleable Iron Floor Flange is fundamental to ensuring compatibility, performance, and compliance within complex systems. These fittings are engineered to meet specific industry standards, guaranteeing their reliability and interchangeability. Key parameters include material grade, typically conforming to ASTM A197 for Cupola Malleable Iron, which defines the minimum tensile strength of 50,000 psi (345 MPa), yield strength of 32,000 psi (220 MPa), and elongation of 10%. These mechanical properties signify the material's ability to withstand significant stress and deformation before failure, crucial for dynamic industrial environments. Threading, a critical aspect for a leak-proof connection, typically adheres to ANSI B1.20.1 for NPT (National Pipe Taper) or ISO 7-1 (BSPT) for conical pipe threads, ensuring a tight seal when properly applied.

Key Specifications for 1/2" Malleable Iron Floor Flange

| Parameter | Value/Description |

|---|---|

| Nominal Pipe Size (NPS) | 1/2" (DN15) |

| Material Grade | ASTM A197 Malleable Iron (Black or Galvanized) |

| Tensile Strength (Min) | 345 MPa (50,000 psi) |

| Yield Strength (Min) | 220 MPa (32,000 psi) |

| Elongation (Min) | 10% |

| Max Working Pressure | 150 PSI (Water, Oil, Gas) |

| Temperature Range | -20°C to 200°C (-4°F to 392°F) |

| Thread Type | NPT (ANSI B1.20.1) or BSPT (ISO 7-1) |

| Number of Bolt Holes | 4 |

| Outer Diameter (Approx.) | 80-85 mm (3.15-3.35 inches) |

| Height (Approx.) | 20-25 mm (0.79-0.98 inches) |

| Surface Finish Options | Black (self-color, rust-preventative oil) or Hot-dip Galvanized |

The maximum working pressure for these fittings is typically rated at 150 PSI for water, oil, and gas applications, a standard performance benchmark that makes the 1/2", 3/4", and 1" Malleable Iron Floor Flange suitable for a wide range of low to medium-pressure systems. Their operational temperature range, spanning from -20°C to 200°C (-4°F to 392°F), highlights their resilience in varying environmental conditions, minimizing the risk of thermal expansion-induced stress or material degradation. The number of bolt holes (typically four) and their precise alignment are crucial for secure mounting, whether on a solid surface in an industrial setting or as a base for bespoke furniture pieces. For designers and engineers selecting components for critical applications, these detailed technical specifications provide the necessary assurance regarding the part's integrity, durability, and compatibility with other system elements, making the 1/2" floor flange a reliable choice for a multitude of projects.

The surface finish options, black and hot-dip galvanized, cater to both functional and aesthetic requirements. Black malleable iron, with its characteristic dark finish, is often preferred for dry interior applications or industrial aesthetics, typically coated with a rust-preventative oil. Hot-dip galvanized fittings, recognized by their silvery, mottled appearance, offer superior corrosion resistance due to the sacrificial zinc coating, making them ideal for outdoor use, humid environments, or applications involving water and certain chemicals. This dual offering ensures that the 1/2" floor flange can be seamlessly integrated into diverse projects, from structural frameworks to intricate designs using male female coupling for Plumbing Pipe Furniture. Adherence to international quality standards such as ISO 9001 and CE certification further validates the manufacturing process, providing an additional layer of assurance regarding product consistency and performance. Such detailed adherence to engineering specifications and quality benchmarks positions these fittings as indispensable for professionals seeking uncompromising reliability and functional versatility.

Diverse Applications & Real-World Scenarios for Malleable Iron Fittings

The versatility of malleable iron fittings, encompassing the 1/2", 3/4", and 1" Malleable Iron Floor Flange, as well as various male female coupling for Plumbing Pipe Furniture, extends their utility across an remarkably broad spectrum of industries and applications. In traditional industrial settings, these fittings are foundational components in fluid conveyance systems. They are widely employed in general plumbing for water, steam, gas, and oil lines due to their robust construction and reliable threaded connections that minimize leakage. Their durability makes them suitable for fire suppression systems, where integrity under pressure is non-negotiable, and in HVAC (heating, ventilation, and air conditioning) systems, where they manage the flow of various mediums across a range of temperatures. For instance, a 1/2" floor flange might serve as a crucial anchoring point for a domestic gas line, providing a stable, secure connection to the wall or floor structure, demonstrating its integral role in maintaining safety and operational efficiency within residential and commercial buildings.

Beyond conventional plumbing, malleable iron fittings have found a significant niche in more specialized industrial applications. In the petrochemical sector, their resistance to moderate pressures and temperatures makes them viable for non-corrosive fluid transport, contributing to the safe and efficient operation of refineries and chemical plants. Similarly, in the metallurgy industry, they are used in various utility lines, supporting processes that demand reliable infrastructure. The inherent strength and shock resistance of malleable iron ensure these fittings can withstand the rigors of heavy industrial environments, including minor impacts and vibrations, without compromising structural integrity. This resilience is a key differentiator when selecting materials for long-term installations where reliability and minimal downtime are paramount. An example includes their use in industrial machinery's cooling water circulation systems, where the 1/2" fitting's compact size and robust nature allow for precise, space-efficient connections.

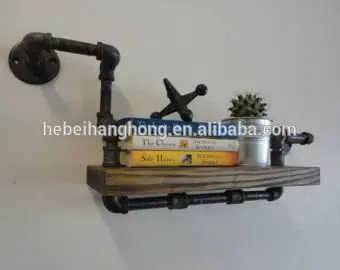

Perhaps one of the most innovative and rapidly growing applications for malleable iron fittings is in the realm of "Plumbing Pipe Furniture" and interior design. The distinctive industrial aesthetic of black or galvanized fittings, including the 1/2" floor flange and various male female coupling components, has led to their widespread adoption in creating bespoke tables, shelving units, lighting fixtures, garment racks, and even beds. Their robust nature provides both structural support and a unique visual appeal that complements modern, minimalist, and rustic decors. For instance, a small business owner in Brooklyn, NY, utilized our 3/4" malleable iron pipe and 1/2" Malleable Iron Floor Flange to construct a custom display shelving system for their boutique. They reported, "The ease of assembly and the sturdy, authentic industrial look of these flanges were exactly what we needed. They truly transformed our retail space and have held up exceptionally well under daily use." This feedback underscores the products' adaptability and positive impact in creative, functional applications. The simplicity of assembly, coupled with the structural integrity provided by these fittings, makes them an attractive choice for both DIY enthusiasts and professional designers seeking durable and aesthetically appealing solutions.

Technical Advantages and Tailored Customization Solutions

The enduring appeal and widespread adoption of 1/2", 3/4", and 1" Malleable Iron Floor Flanges, alongside male female coupling for Plumbing Pipe Furniture, stem from their inherent technical advantages. Malleable iron's unique microstructure, characterized by temper carbon nodules in a ferritic matrix, imparts a superior combination of strength and ductility. Unlike grey cast iron, which is brittle, malleable iron can withstand significant shock and vibration without fracturing, a critical attribute in dynamic industrial environments and for structural applications like furniture. This ductility also makes the material highly resistant to cracking during installation, tightening, or under operational stress, contributing to a longer service life and reduced maintenance. The precise threading achieved through CNC machining ensures a consistently tight and leak-proof connection, vital for fluid conveyance systems where safety and efficiency are paramount. This precision also simplifies installation, reducing labor costs and project timelines, a significant advantage for large-scale industrial projects.

Furthermore, the excellent machinability of malleable iron allows for the production of fittings with tight tolerances and complex geometries, ensuring compatibility with a wide range of pipes and components. This material also exhibits good corrosion resistance, especially when galvanized, providing a sacrificial zinc layer that protects the underlying iron from rust and degradation in harsh environments. This makes galvanized 1/2" malleable iron fittings suitable for outdoor installations, marine applications, and systems handling corrosive fluids, significantly extending their functional lifespan compared to untreated materials. The cost-effectiveness of malleable iron production, combined with its robust performance characteristics, offers a compelling value proposition for B2B clients seeking reliable and economical solutions for their infrastructure and design needs. For instance, the ease with which these fittings can be assembled and disassembled without special tools further enhances their appeal in both permanent installations and temporary structures, such as exhibition stands or modular furniture systems.

Beyond standard offerings, modern manufacturing capabilities allow for extensive customization, addressing the unique requirements of diverse projects. This includes providing 1/2", 3/4", and 1" Malleable Iron Floor Flanges with specific finishes beyond black and galvanized, such as powder coating in various colors to match architectural aesthetics or specialized coatings for enhanced chemical resistance. Custom threading options, including metric threads or non-standard pitches, can be accommodated to ensure seamless integration with existing systems or bespoke components. Furthermore, manufacturers can produce custom designs based on client blueprints, encompassing unique flange shapes, additional bolt holes, or integrated features for specialized mounting or connection purposes. This bespoke manufacturing service leverages advanced CAD/CAM technologies and flexible production lines, ensuring that even highly specialized needs for male female coupling for Plumbing Pipe Furniture or industrial systems can be met with precision and efficiency, upholding the highest standards of quality and performance for every customized solution.

Manufacturer Comparison and Why Choose Us for Your Malleable Iron Fittings

When selecting a supplier for critical components such as 1/2", 3/4", and 1" Malleable Iron Floor Flanges and male female coupling for Plumbing Pipe Furniture, discerning B2B clients prioritize factors beyond mere price. The true value lies in a manufacturer's commitment to quality, adherence to international standards, operational experience, and ability to provide comprehensive support. Here’s a comparative overview highlighting key aspects that differentiate leading manufacturers and underscore our commitment to excellence:

Comparative Analysis of Malleable Iron Fittings Manufacturers

| Feature | Manufacturer A (Generic) | Manufacturer B (Generic) | Our Company |

|---|---|---|---|

| Certifications & Standards | ISO 9001, basic domestic standards | ISO 9001, select international (e.g., DIN) | ISO 9001:2015, CE, ANSI, ASTM, UL (where applicable for specific products) |

| Product Range Focus | Standard plumbing fittings | Limited range, some specialty items | Comprehensive: Standard (1/2", 3/4", 1") and Custom Floor Flanges, Male Female Couplings, diverse fittings |

| Customization Capability | Minimal or none | Basic modifications only | Extensive: Custom designs, finishes, threading; rapid prototyping |

| Quality Control Process | Batch sampling, basic visual checks | Standard testing, some in-process checks | Full spectrum: Raw material analysis, in-process dimensional & mechanical tests, hydrostatic testing, final inspection per lot |

| Lead Time & Delivery | Variable, often long for custom orders | Standard, subject to raw material availability | Optimized supply chain; reliable, transparent schedules; expedited options for urgent needs |

| Service & Support | Limited post-sales support | Standard customer service | Dedicated account managers, technical support, comprehensive warranty, responsive after-sales service |

| Industry Experience | Newer or regional players | Established, but may lack niche expertise | Over 15 years experience, recognized industry leader in both industrial and decorative fittings |

Our company distinguishes itself through a steadfast commitment to unparalleled quality and comprehensive customer satisfaction. With over 15 years of focused expertise in manufacturing malleable iron fittings, we adhere rigorously to international standards such as ISO 9001:2015, ensuring that every 1/2" Malleable Iron Floor Flange, 3/4" fitting, or male female coupling we produce meets the highest benchmarks for material composition, dimensional accuracy, and mechanical performance. Our state-of-the-art production facilities incorporate advanced casting, malleabilizing, and CNC machining technologies, allowing for precision engineering that guarantees leak-proof threaded connections and superior durability across our entire product range.

Furthermore, our dedication to supporting our clients extends to offering robust customization solutions, from specialized finishes and non-standard threading to the development of entirely new product geometries based on specific project requirements for industrial systems or bespoke Plumbing Pipe Furniture. This flexibility, combined with our efficient supply chain management, ensures reliable delivery schedules and competitive pricing without compromising quality. Our long-standing relationships with global partners and a portfolio of successful large-scale industrial projects serve as a testament to our authoritativeness and trustworthiness in the market. We provide dedicated technical support and a transparent warranty policy, reinforcing our commitment to building lasting partnerships based on mutual trust and consistent product excellence. Choosing us means opting for a partner that prioritizes your project's success through superior product quality, expert technical assistance, and dependable service, making us the preferred choice for discerning B2B buyers of 1/2" and other malleable iron fittings.

Ensuring Trust: FAQs, Warranty, and Customer Support

Building trust with our B2B clients is paramount, and it extends beyond just delivering high-quality 1/2", 3/4", and 1" Malleable Iron Floor Flanges or male female coupling for Plumbing Pipe Furniture. It involves providing clear information, robust support, and steadfast assurances. Here, we address common inquiries and outline our commitment to transparency and reliability.

Frequently Asked Questions (FAQs)

Q1: What is malleable iron and how does it differ from cast iron?

A1: Malleable iron is a type of cast iron that has undergone a specific heat treatment (malleabilizing) to convert the carbon content into temper carbon nodules. This process transforms the inherently brittle white cast iron into a ductile material with significantly improved tensile strength, impact resistance, and machinability. Unlike grey cast iron, which is brittle and fractures easily, malleable iron can withstand deformation without breaking, making it ideal for applications requiring robust and resilient fittings like the 1/2" floor flange.

Q2: What is the difference between black and galvanized malleable iron fittings?

A2: Black malleable iron fittings have a natural, untreated surface, often coated with a rust-preventative oil for protection during shipping and storage. They are typically used for dry interior applications or where a rustic, industrial aesthetic is desired. Galvanized malleable iron fittings, conversely, are hot-dip galvanized, meaning they are coated with a layer of zinc. This zinc layer provides superior corrosion resistance, making them suitable for outdoor use, humid environments, or applications involving water and certain chemicals. The choice between black and galvanized for a 1/2" fitting often depends on the environmental conditions and aesthetic preference.

Q3: Do your fittings meet international standards?

A3: Absolutely. All our malleable iron fittings, including the 1/2" Malleable Iron Floor Flange, are manufactured in strict adherence to international quality and performance standards such as ISO 9001:2015 for quality management systems, ANSI B1.20.1 for NPT pipe threads, and ASTM A197 for the malleable iron material specification. Depending on the product and region, our fittings may also carry certifications like CE or UL/FM, ensuring their suitability for global markets and specific regulatory requirements.

Q4: Can these fittings be used outdoors or in high-pressure applications?

A4: Galvanized malleable iron fittings are ideal for outdoor and humid environments due to their enhanced corrosion resistance. While they are robust, our fittings are generally rated for up to 150 PSI (Water, Oil, Gas) working pressure. For very high-pressure applications, specialized fittings designed for those conditions would be recommended. It's crucial to consult the specific product's technical data sheet for its exact pressure and temperature ratings to ensure suitability for your intended application, especially when using a 1/2" pipe in a critical system.

Delivery Cycle Information

Our streamlined production process and efficient logistics network ensure timely delivery of your orders. Standard stock items, including the most common 1/2", 3/4", and 1" Malleable Iron Floor Flanges, typically ship within 7-14 business days. For large-volume orders or customized products like bespoke male female coupling for Plumbing Pipe Furniture, lead times may vary and will be communicated clearly at the time of quotation. We work closely with trusted freight partners to provide reliable global shipping options, offering both sea and air freight depending on your urgency and budget. Our goal is to ensure your project timelines are met with precision and efficiency.

Quality Assurance & Warranty Policy

We stand behind the quality and performance of every malleable iron fitting we manufacture. Our products undergo rigorous quality control at every stage of production, from raw material inspection to final product testing, ensuring they meet or exceed industry standards. We offer a comprehensive warranty against manufacturing defects and material failures under normal use conditions. The specific terms and duration of the warranty will be provided with your purchase agreement. This commitment reflects our confidence in our products and our dedication to your long-term satisfaction. Our quality assurance system adheres to ISO 9001:2015, providing a structured framework for continuous improvement and defect prevention, thereby reinforcing the trustworthiness of our 1/2" and other fittings.

Dedicated Customer Support

Our commitment to our clients extends far beyond the point of sale. We provide dedicated customer support to assist with technical queries, product selection, order tracking, and any post-sales inquiries. Our team of experienced professionals is readily available to offer expert advice, helping you select the correct 1/2" fitting or design a complex system using our male female couplings. You can reach us via phone, email, or through our website's contact form. We pride ourselves on responsive, knowledgeable, and proactive support, ensuring a seamless experience from initial inquiry to project completion. Your success is our priority, and we are here to support you every step of the way.

Conclusion

The 1/2" Malleable Iron Floor Flange, alongside its 3/4" and 1" counterparts and specialized male female coupling for Plumbing Pipe Furniture, stands as a testament to enduring material science and precision engineering. Its unique blend of strength, ductility, and machinability makes it an indispensable component across a multitude of industries, from critical fluid conveyance systems in petrochemical and water treatment plants to innovative structural elements in modern interior design. The rigorous manufacturing processes, coupled with stringent quality control measures, ensure that these fittings provide unmatched reliability, long service life, and consistent performance under diverse operating conditions.

As the demand for both robust industrial solutions and aesthetically appealing design components continues to grow, malleable iron fittings remain at the forefront, adaptable to evolving project requirements through comprehensive customization options. Our commitment to exceeding international standards, coupled with our extensive industry experience and unwavering dedication to customer support, positions us as the trusted partner for all your malleable iron fitting needs. By choosing our products, you invest in components that not only meet but surpass the highest benchmarks for quality, performance, and value, ensuring the success and longevity of your endeavors. The versatility and inherent advantages of the 1/2" floor flange and related products underscore their foundational importance in both traditional industrial applications and the burgeoning field of architectural and decorative pipe furniture, proving their indispensable role in today's dynamic market.

Authoritative References

- American Society for Testing and Materials (ASTM). ASTM A197/A197M-18, "Standard Specification for Cupola Malleable Iron."

- American National Standards Institute (ANSI) & American Society of Mechanical Engineers (ASME). ANSI/ASME B1.20.1-2013, "Pipe Threads, General Purpose (Inch)."

- International Organization for Standardization (ISO). ISO 49:1983, "Malleable cast iron fittings with taper thread for connecting pipes and fittings with taper thread."

- ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International, 1990.

- European Committee for Standardization (CEN). EN 10242:1994, "Threaded pipe fittings in malleable cast iron."

-

1/2" Malleable Iron Pipe Fittings for Furniture & Plumbing

NewsAug.17,2025

-

Urban 3/4" Floor Flange for DIY RH Inspired Shelving

NewsAug.16,2025

-

Vintage Galvanized Pipe Chandelier - Industrial Lighting

NewsAug.15,2025

-

Industrial Pipe Shelf Brackets 'T' - Heavy 3/4" Iron

NewsAug.14,2025

-

Durable 2" Black Malleable Iron Pipe & 3/4" Threaded Fittings

NewsAug.13,2025

-

Malleable Galvanized Iron Pipe Fittings & Key Clamps - Durable

NewsAug.12,2025