-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

نويابىر . 27, 2024 18:49 Back to list

Cast Iron Table Base Manufacturers and Their Unique Offerings in Furniture Industry

The Significance of Cast Iron Table Base Factories in Modern Manufacturing

In today's rapidly evolving manufacturing landscape, cast iron has remained a preferred material for a wide range of applications, particularly in the production of table bases. The steady demand for durable, aesthetically pleasing, and functional furniture has led to the emergence of numerous cast iron table base factories worldwide. This article explores the significance, processes, and innovations associated with these factories, shedding light on how they cater to both consumer needs and industry trends.

The Importance of Cast Iron in Furniture Manufacturing

Cast iron is a robust material known for its longevity and resistance to wear and tear. Its ability to withstand heavy loads while maintaining structural integrity makes it an ideal choice for table bases. In environments ranging from residential dining rooms to bustling restaurants, furniture needs to endure daily use and possible abuse. Factories producing cast iron table bases play a critical role in ensuring that the furniture industry can meet these demands.

Moreover, cast iron has aesthetic appeal. With its ability to be molded into intricate designs, manufacturers can produce vintage-inspired or contemporary table bases that enhance the overall décor of a space. This combination of durability and design flexibility has made cast iron a favored choice among designers and consumers alike.

Manufacturing Processes in Cast Iron Table Base Factories

The production of cast iron table bases involves several key processes, starting with the creation of patterns. A detailed design is crafted, often from wood or metal, which serves as a prototype for the casting process. Once the pattern is ready, it is used to create molds, typically made of sand mixed with a bonding agent. This mixture retains the shape of the pattern after the pattern is removed, forming a cavity for the molten iron.

cast iron table base factories

The next step is the melting of iron, which is done in a furnace. Once the iron reaches the required temperature, it is poured into the molds. Cooling and solidification follow, which can take several hours depending on the thickness of the product. After the cast pieces cool, they are removed from the molds and subjected to various finishing processes. This may include grinding, sanding, and painting to achieve the desired aesthetics and finish quality.

Recent innovations in technology have improved the efficiency and accuracy of these manufacturing processes. Automation has decreased manual labor, while advancements in furnace technology have allowed for better energy efficiency and reduced emissions. These improvements not only enhance productivity but also contribute to sustainable manufacturing practices.

Innovations in Design and Functionality

As consumer preferences shift towards custom and personalized products, cast iron table base factories have embraced innovative designs that cater to diverse tastes. Customization options allow clients to choose the style, finish, and size of their table bases, accommodating a broader range of interior designs. Furthermore, some manufacturers are exploring the integration of modern technologies, such as 3D printing for prototyping and detailed design work.

Sustainability has also become a key focus area. Many cast iron factories are now incorporating recycled materials into their production processes, reducing their environmental footprint. By utilizing reclaimed iron and minimizing waste, these factories are appealing to a growing demographic that prioritizes eco-friendly practices.

Conclusion

Cast iron table base factories play a fundamental role in the furniture manufacturing industry, providing durable and stylish components that meet the needs of modern consumers. Through a combination of traditional craftsmanship and innovative technology, these factories have adapted to the changing landscape of manufacturing while holding onto the timeless qualities that make cast iron a beloved material. As sustainability and customization continue to shape consumer preferences, the future of cast iron table base production looks promising, ensuring that this material remains a staple in furniture design for years to come. The harmonious blend of durability, aesthetics, and innovation solidifies the importance of cast iron table base factories as they forge ahead in the competitive world of manufacturing.

-

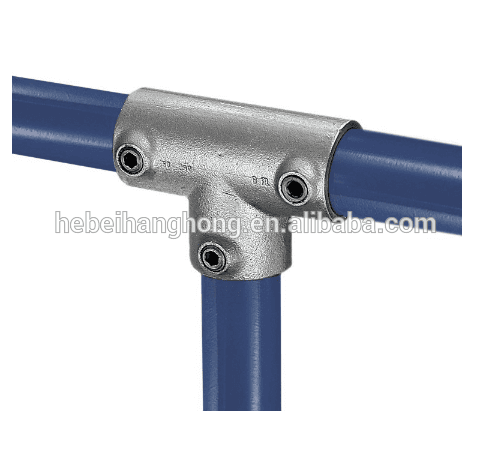

Malleable Galvanized Iron Pipe Fittings & Key Clamps - Durable

NewsAug.12,2025

-

Industrial Steampunk Swing Towel Rail - 3-Bar Pipe Design

NewsAug.11,2025

-

1" Black Malleable Iron 4-Way Cross Pipe Plumbing Fitting

NewsAug.10,2025

-

1/2"-1" Malleable Iron Fittings for DIY Metal Pipe Brackets

NewsAug.09,2025

-

3/4 1/2 Inch Malleable Iron Floor Wall Flange - Industrial Decor

NewsAug.08,2025

-

1/2" DN15 Cast Iron Pitting Floor Flange - Industrial Pipe Mount

NewsAug.07,2025