-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

Dec . 21, 2024 21:49 Back to list

galvanized malleable iron manufacturers

The Evolution and Importance of Galvanized Malleable Iron in Manufacturing

Galvanized malleable iron is a remarkable material that has played a significant role in various industries due to its unique combination of strength, flexibility, and resistance to corrosion. This article delves into the characteristics, manufacturing process, applications, and the landscape of galvanized malleable iron manufacturers.

Understanding Galvanized Malleable Iron

Malleable iron is a form of cast iron that is designed to be more versatile and ductile than traditional cast iron. The malleability of the iron is achieved through a heat treatment process known as “tempering.” This process alters its microstructure, making it less brittle and enhancing its strength.

The term “galvanized” refers to the process of coating iron or steel with zinc to prevent rusting. The galvanization process can be achieved through hot-dip galvanizing or electro-galvanizing, creating a protective layer that significantly increases the material’s lifespan, especially when exposed to harsh environments.

Manufacturing Process

The production of galvanized malleable iron involves several key steps. Initially, the raw material, which is typically iron ore, is melted down in a furnace to create molten iron. Once the desired temperature is reached, the molten iron is poured into molds, where it solidifies into the rough shape of the finished product.

After the initial casting, the malleable iron undergoes a heat treatment process to enhance its malleability and strength characteristics. The iron is heated to a specific temperature before being allowed to cool slowly. This transformation alters the internal structure of the iron, making it more adaptable while retaining a high level of durability.

The final step involves galvanization, where the treated iron is subjected to a zinc coating process. This can be done by immersing the iron parts in molten zinc (hot-dip galvanizing) or by applying a layer of zinc through electrochemical processes. Once galvanized, the end product not only has improved corrosion resistance but also a distinctive finish which can be aesthetically pleasing as well.

Applications of Galvanized Malleable Iron

galvanized malleable iron manufacturers

Galvanized malleable iron is widely used in several industries due to its superior properties. One of the most common applications is in the manufacturing of pipes and fittings. The durable and corrosion-resistant nature of galvanized malleable iron makes it an ideal choice for plumbing and construction projects.

Additionally, this material is often utilized in the production of hardware, such as brackets, couplings, and connectors, where both strength and resistance to environmental factors are critical. Furthermore, galvanized malleable iron is favored in the agricultural sector for constructing irrigation systems and equipment, ensuring longevity despite exposure to moisture and chemicals.

Electricity and telecommunications infrastructure is another area where galvanized malleable iron finds extensive use. It is commonly used in the manufacture of utility poles and mounting brackets, protecting them from environmental degradation and ensuring they stand the test of time.

The Landscape of Manufacturers

The market for galvanized malleable iron is thriving, driven by a steady demand across construction, agriculture, and manufacturing sectors. Several manufacturers specialize in producing this material, each striving to maximize quality and efficiency in the production process.

Leading manufacturers often invest in advanced technologies and sustainable practices, ensuring that they meet both local and international standards. This focus on innovation helps improve production efficiency while reducing the environmental impact of manufacturing processes.

As industries evolve, the continuous development of galvanized malleable iron products becomes paramount. Manufacturers are exploring new alloys and treatment processes to further enhance the properties of malleable iron, aiming to meet the growing needs of modern applications.

Conclusion

In conclusion, galvanized malleable iron stands as a vital component in modern manufacturing. Its unique blend of malleability, strength, and corrosion resistance makes it indispensable in various sectors. As manufacturers continue to innovate and refine their processes, the future of galvanized malleable iron seems promising, ensuring its position as a critical material in the global market. As we look to the future, the importance of galvanized malleable iron will undoubtedly continue to grow, driven by the relentless pursuit of durability and sustainability in industrial applications.

-

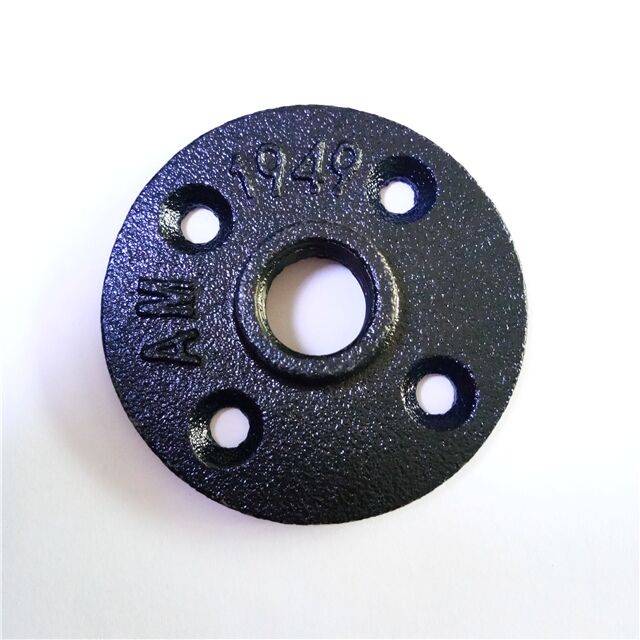

4X 3/4 Malleable Iron Pipe Fittings Floor Flange 3/4" Threaded BSP Wall Mount

NewsMar.07,2025

-

Galvanized 24yy 3/4"flange key clamp used for 26.9mm pipe

NewsMar.07,2025

-

3/4inch malleable cast iron design plumbing pipe rustic industrial pipe shelf

NewsMar.07,2025

-

3/4'' black iron floor flange for plumbing pipe table

NewsMar.07,2025

-

Malleable Iron Pipe Floor Threaded Fitting Black Flange

NewsMar.07,2025

-

china brass pipe fittings

NewsMar.07,2025