-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

Desemba . 01, 2024 19:51 Back to list

Leading Manufacturer of Pipe Flanges and Fittings for Diverse Industrial Applications

Understanding Pipe Flange Fitting Manufacturers A Comprehensive Overview

In the world of industrial piping systems, pipe flange fittings are essential components that enable the safe and efficient connection of pipes. Manufacturers of these fittings play a crucial role in ensuring that the products meet the necessary standards of quality, durability, and functionality. This article will provide insight into the importance of pipe flange fittings, the manufacturing process, key standards, and considerations when selecting a manufacturer.

The Importance of Pipe Flange Fittings

Pipe flange fittings serve as crucial points for joining pipes, valves, pumps, and other equipment in various industries, including oil and gas, water treatment, chemical processing, and construction. They provide a reliable method for creating strong and leak-proof connections, essential for maintaining system integrity under pressure and temperature variations. Properly designed and manufactured flange fittings can also facilitate easy disassembly for maintenance and repairs, reducing downtime and associated costs.

Types of Pipe Flanges

There are several types of pipe flanges, each designed for specific applications. The most common types include

1. Weld Neck Flanges These flanges are welded to the pipe, providing strength and pressure containment, commonly used in high-pressure applications. 2. Slip-On Flanges These flanges slip over the pipe and are welded in place. They are easier to align and are often used in lower-pressure applications.

3. Blind Flanges Used to seal the ends of piping systems, blind flanges do not have holes and are essential for isolating sections of a system for maintenance.

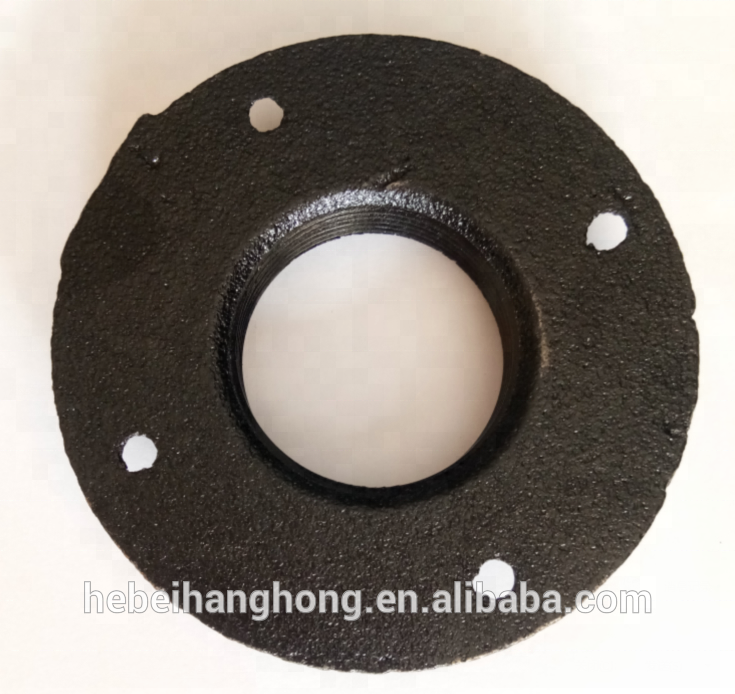

4. Threaded Flanges These flanges have internal threads and can be screwed onto a pipe, making them suitable for systems that cannot be welded.

5. Socket Weld Flanges These flanges are inserted into a pipe and welded, ideal for high-pressure applications.

Understanding the specific requirements of your project will help in selecting the right type of flange.

The Manufacturing Process

The manufacturing of pipe flange fittings involves several key steps, ensuring that each product meets industry standards and customer specifications

. The process typically includespipe flange fitting manufacturer

1. Material Selection Flanges can be made from various materials like stainless steel, carbon steel, and plastic. Each material offers different properties regarding strength, corrosion resistance, and temperature tolerance.

2. Forming and Machining Depending on the type of flange, metal is either forged or machined into the desired shape. Precision machining is vital to ensure that flanges fit correctly and function effectively.

3. Surface Treatment To enhance durability and resistance to environmental factors, flanges may undergo various surface treatments like galvanization, coating, or polishing.

4. Quality Control Rigorous testing and inspection processes are employed to ensure that each flange meets specified standards. This may include pressure testing, dimensional verification, and material testing.

5. Certification and Compliance Manufacturers often obtain certifications such as ISO or ASME to demonstrate compliance with industry quality standards, which further assures customers of the reliability of the products.

Considerations When Selecting a Manufacturer

Selecting a pipe flange fitting manufacturer is a critical decision that can impact the overall quality and safety of your piping system. Here are some factors to consider

- Experience and Reputation A manufacturer with a strong industry presence and proven track record is likely to deliver high-quality products.

- Customization Capabilities If your project requires specific designs or materials, ensure the manufacturer can accommodate custom requests.

- Certifications and Standards Verify that the manufacturer adheres to recognized standards and has the necessary certifications, which reflects their commitment to quality.

- Customer Support Strong technical support and customer service can aid in making informed purchasing decisions and enhance the overall experience.

Conclusion

Pipe flange fittings are vital components in the efficient and safe operation of piping systems across various industries. Understanding their importance and the manufacturing process, along with thoughtful consideration when selecting a manufacturer, can significantly contribute to the success of any project. Investing in high-quality flanges from a reputable manufacturer ensures reliability and longevity, ultimately making a difference in operational efficiency and safety.

-

Durable 3/4" Malleable Iron Floor Flange - 3-Hole

NewsAug.06,2025

-

In Stock: 1/2" & 3/4" Galvanized Malleable Iron Floor Flanges

NewsAug.04,2025

-

Premium Black & Galvanized Key Clamp Fittings for Furniture Joints | Durable

NewsAug.03,2025

-

Wholesale China Malleable Cast Iron Decorative Floor Flanges

NewsAug.02,2025

-

3/4" Reinforced Bronze Flange Iron Pipe Floor Fitting | Threaded

NewsAug.01,2025

-

3/4 Inch Black Malleable Iron Floor Flange - Heavy Duty

NewsJul.31,2025