-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

Oct . 01, 2024 11:26 Back to list

DN15 Flanges Manufacturers Offering High-Quality Solutions for Your Industrial Needs

Understanding Flange DN15 Manufacturers A Comprehensive Overview

When it comes to industrial piping systems, flanges play a crucial role in ensuring proper connections between various components. Among the many types of flanges available, the DN15 flange is particularly significant in smaller diameter piping systems. In this article, we will explore the features, importance, and considerations for selecting a reliable DN15 flange manufacturer.

What is a DN15 Flange?

The term DN stands for Diameter Nominal, which is a standard dimension used in the European piping system to denote the nominal size of a pipe or flange. A DN15 flange corresponds to a nominal pipe size of 15 millimeters in diameter. DN15 flanges are commonly used in various applications, including water supply, chemical processing, and HVAC systems, among others. They are typically manufactured according to specific standards, such as ISO or ASME, ensuring they meet industry requirements for strength and durability.

Importance of Quality in Flange Manufacturing

The importance of choosing a reputable DN15 flange manufacturer cannot be overstated. Flanges are subjected to considerable pressure, temperature fluctuations, and exposure to chemicals, making the choice of materials and production methods critical. High-quality flanges ensure secure seals and prevent leaks, which can lead to costly downtime and safety hazards in industrial operations. As such, manufacturers must adhere to stringent quality assurance processes and relevant industry standards.

Key Considerations When Selecting a DN15 Flange Manufacturer

1. Material Quality Flanges are available in various materials, including stainless steel, carbon steel, and plastic. The choice of material affects the flange's durability, pressure rating, and resistance to corrosion. When selecting a manufacturer, verify the raw materials used in their production process to ensure they meet your project’s specific requirements.

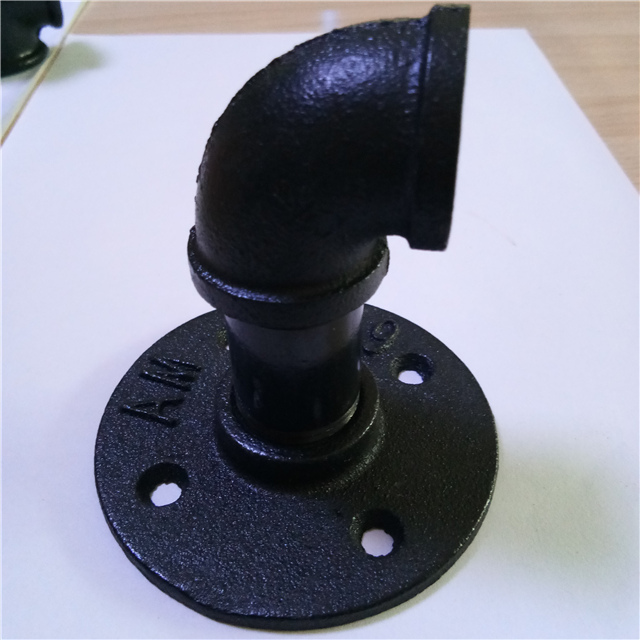

flange dn15 manufacturer

2. Manufacturing Standards Look for manufacturers who adhere to established manufacturing standards, such as ASTM, ANSI, or ISO specifications. This ensures that the flanges produced are of high quality and can withstand the operational conditions they will be subjected to.

3. Certifications and Accreditations A reputable manufacturer should possess certifications that vouch for their quality management system. Certifications such as ISO 9001 demonstrate a commitment to maintaining high-quality production processes and customer satisfaction.

4. Experience and Reputation Consider the manufacturer's experience in the industry. Companies with a proven track record and positive customer reviews are often more reliable. An experienced manufacturer will have a better understanding of the complexities involved in flange production and can offer tailored solutions to meet your needs.

5. Customization Options Depending on your specific application, you may require customized flanges. Check if the manufacturer offers customization in terms of dimensions, materials, and finishes to suit your unique specifications.

6. Technical Support and After-Sales Service Good manufacturers provide comprehensive technical support and after-sales service. This includes assistance with installation, maintenance advice, and solutions for any issues that may arise after purchase.

Conclusion

Choosing the right DN15 flange manufacturer is crucial for ensuring the efficiency and safety of your piping systems. By focusing on quality materials, manufacturing standards, certifications, experience, customization options, and technical support, you can select a manufacturer that meets your needs. Investing time in finding a reliable supplier will pay off in the long run, providing peace of mind and enhancing the durability of your piping infrastructure. Whether you are in construction, manufacturing, or any other industry relying on valves and flanges, understanding the significance of a dependable DN15 flange manufacturer is integral to your operational success.

-

Durable DN15 1/2" Malleable Iron Threaded Floor Flange

NewsAug.18,2025

-

1/2" Malleable Iron Pipe Fittings for Furniture & Plumbing

NewsAug.17,2025

-

Urban 3/4" Floor Flange for DIY RH Inspired Shelving

NewsAug.16,2025

-

Vintage Galvanized Pipe Chandelier - Industrial Lighting

NewsAug.15,2025

-

Industrial Pipe Shelf Brackets 'T' - Heavy 3/4" Iron

NewsAug.14,2025

-

Durable 2" Black Malleable Iron Pipe & 3/4" Threaded Fittings

NewsAug.13,2025