-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

Oct . 18, 2024 17:39 Back to list

Ninety Degree Black Elbow Manufacturers and Their Quality Production Standards

The Growing Demand for Black 90 Degree Elbow Fittings A Focus on Factories and Production

In the realm of plumbing and construction, the significance of robust and durable fittings cannot be overstated. Among these, the black 90 degree elbow fitting has emerged as a crucial component. Used extensively in various applications, including residential plumbing, commercial infrastructure, and industrial projects, these fittings play a vital role in managing the direction of piping systems. This article delves into the factories producing black 90 degree elbow fittings, examining their importance, production processes, and the increasing demand in today’s market.

The Growing Demand for Black 90 Degree Elbow Fittings A Focus on Factories and Production

Factories that specialize in the production of black 90 degree elbow fittings are equipped with advanced technological capabilities. Automated machinery and high-tech manufacturing processes ensure precision and consistency in each fitting produced. The production begins with raw materials, which are carefully selected based on the specifications required for the fittings. For instance, the quality of the steel used can significantly impact the fitting’s durability and resistance to corrosion, making material selection a critical first step.

black 90 deg elbow factories

Once the materials are sourced, the manufacturing process involves several stages, including molding, welding, and finishing. The molding process shapes the raw material into the desired elbow configuration, while welding ensures that the joints are secure and leak-proof. Quality control measures are enforced throughout to ensure that every fitting meets industry standards. Tests for pressure resistance and durability are paramount, as these fittings are often subjected to high stress in real-world applications.

As the construction industry experiences growth, particularly in emerging economies, the demand for black 90 degree elbows is on the rise. Infrastructure projects, including roads, bridges, and utilities, utilize these fittings extensively, thereby boosting their market presence. Additionally, the ongoing trend of retrofitting and upgrading existing plumbing systems in older buildings has further fueled the need for reliable piping solutions.

Moreover, sustainable practices are now at the forefront of manufacturing operations, with many factories implementing eco-friendly processes. This includes recycling scrap materials and using energy-efficient machinery, which not only reduces costs but also appeals to environmentally conscious consumers and businesses. As sustainability becomes a priority in all sectors, factories producing black 90 degree elbows are adapting to meet these new expectations.

In conclusion, the factories producing black 90 degree elbow fittings serve as the backbone of modern plumbing and construction industries. Their commitment to quality manufacturing processes, coupled with a keen awareness of market demands, positions them as essential players in the supply chain. As urbanization continues to rise and the need for reliable infrastructure strengthens, the role of these factories is set to grow even more significant. In an era where efficiency, sustainability, and durability are key, black 90 degree elbows remain a vital component, ensuring the seamless operation of piping systems across various sectors.

-

Premium Malleable Galvanized Cast Iron Pipe Fittings & Key Clamps

NewsJul.30,2025

-

3/4 inch Black Finish Pipe Nipple for Home Decor – Durable & Stylish

NewsJul.30,2025

-

Hot galvanized and black malleable iron key clamp for strong pipe fitting

NewsJul.29,2025

-

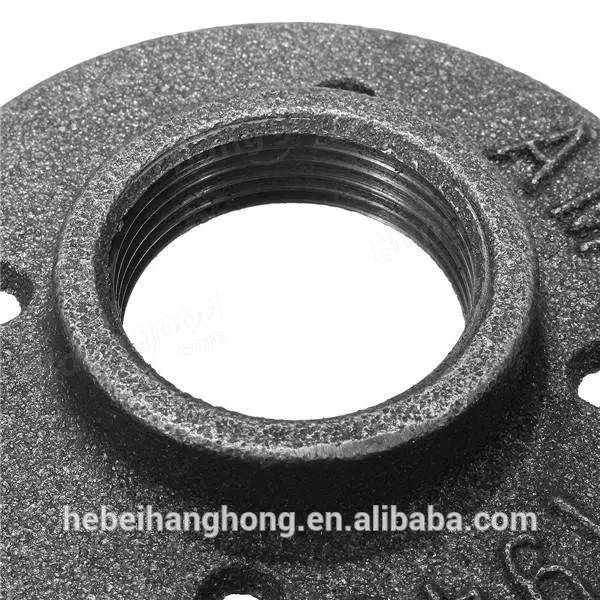

Black Malleable Threaded Floor Flange Iron BSP Pipe Fittings, 1/2" 3/4" 1"

NewsJul.29,2025

-

3/4" Black Malleable Iron Straight Coupling Fitting Pipe BSPT - Durable & Leak-Proof

NewsJul.29,2025

-

NPT Threaded Assessed Supplier Alibaba Hot Sell | Reliable Fittings

NewsJul.28,2025