-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

දෙසැ. . 31, 2024 03:53 Back to list

nipple galvanized male threaded manufacturer

The Importance of Quality in Nipple Galvanized Male Threaded Products A Manufacturer's Perspective

In the realm of industrial fittings and piping, nipple galvanized male threaded products play a crucial role. These items are essential for connecting pipes in various systems, ensuring a smooth flow of fluids with minimized leakage. As a manufacturer in this sector, understanding the significance of quality, the processes involved in production, and the market demands is vital for success.

Understanding Nipple Galvanized Male Threaded Products

Nipple fittings are short pieces of pipe that have male threads on both ends. They are often used to join two female-threaded items. In this case, galvanized refers to the zinc coating applied to the steel, which serves as a protective layer against corrosion. The male threading allows for a secure connection with female threaded counterparts, making it suitable for various applications, including plumbing, manufacturing, and oil and gas industries.

The Manufacturing Process

Manufacturing nipple galvanized male threaded products involves several stages, each requiring precision and quality control. The processes typically include

1. Material Selection High-grade steel is selected for durability and strength. The steel must undergo tests to ensure it can withstand the pressures and conditions it will be exposed to.

2. Cutting and Shaping The steel is cut to desired lengths. This step is crucial, as the dimensions must meet industry standards for fitting compatibility.

3. Threading Male threads are applied using CNC (computer numerical control) machines. This technology ensures that the threads are consistent and meet the required specifications.

4. Galvanization After threading, the raw metal is dipped in molten zinc or undergoes an electroplating process to apply a protective coating. This step is vital for enhancing the corrosion resistance of the finished product, thereby extending its lifespan.

5. Quality Control Each batch undergoes rigorous testing to check for defects and to ensure dimensional accuracy. This may include pressure testing, visual inspections, and adherence to safety standards.

nipple galvanized male threaded manufacturer

6. Packaging and Distribution Finally, products are packaged securely to prevent damage during transportation. Proper labeling, dimensions, and specifications must be included to facilitate easy identification by customers.

Key Considerations for Manufacturers

For manufacturers, maintaining high-quality standards is paramount. Several factors can influence product quality and overall satisfaction, including

- Quality of Raw Materials Sourcing superior raw materials is the first step toward ensuring quality. Collaborating with reputable suppliers is crucial.

- Skilled Workforce Employing skilled workers and providing them with ongoing training can greatly improve production quality. Workers must understand the machinery and the significance of precision in manufacturing.

- Technological Advancements Adopting the latest manufacturing technologies can enhance efficiency and product consistency. Investing in machines with advanced capabilities can help meet growing market demands more effectively.

- Customer Feedback Listening to customer feedback is invaluable for continuous improvement. Customers often provide insights into practical uses and performance issues, which can guide product refinements.

Market Demand and Future Trends

The demand for nipple galvanized male threaded products is expected to rise, driven by various sectors such as construction, water supply, and oil extraction. As infrastructure projects increase globally, the need for reliable fittings will also grow. Moreover, the rise of sustainable practices prompts manufacturers to seek environmentally friendly galvanizing processes that reduce waste and emissions.

In conclusion, the role of nipple galvanized male threaded products is critical in the industrial sector. By focusing on quality during the manufacturing process and adapting to market needs, manufacturers can ensure that they remain competitive while meeting customer expectations. As industries evolve, staying ahead of trends and maintaining a commitment to excellence will define the success of manufacturers in this essential field.

-

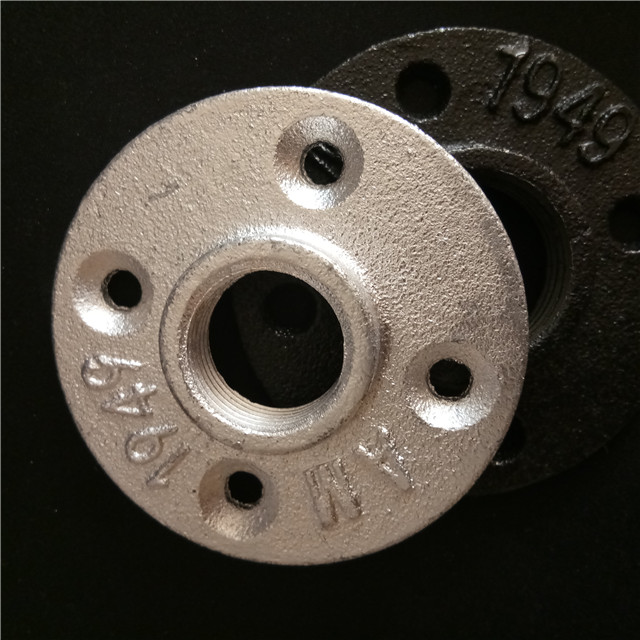

Black Malleable Cast Iron Floor Flange 1/2" BSPT, 3-Hole

NewsAug.22,2025

-

3/4 inch Black Finish Pipe Nipple for Home Decor & DIY

NewsAug.21,2025

-

3/4" Black Malleable Iron Floor Flange - Durable Pipe Fittings

NewsAug.19,2025

-

Durable DN15 1/2" Malleable Iron Threaded Floor Flange

NewsAug.18,2025

-

1/2" Malleable Iron Pipe Fittings for Furniture & Plumbing

NewsAug.17,2025

-

Urban 3/4" Floor Flange for DIY RH Inspired Shelving

NewsAug.16,2025