-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

Дек . 05, 2024 02:55 Back to list

type of flange factory

Types of Flange Factories An Overview

Flanges are critical components in piping systems, used for connecting pipes, valves, pumps, and other equipment to create a secure and leak-proof joint. The manufacturing of flanges takes place in specialized facilities known as flange factories. These factories produce a variety of flange types to meet diverse industrial requirements. In this article, we will explore the different types of flange factories, the processes involved in flange manufacturing, and the various applications of flanges.

Types of Flange Factories

Flange factories can be categorized based on the materials they use and the flanges they produce. The most common types of flange factories include

1. Steel Flange Factories These facilities focus on manufacturing steel flanges, which are widely used in industrial applications due to their high strength and durability. Steel flanges can be made from various grades, including carbon steel, stainless steel, and alloy steel. The production process typically involves forging or machining processes to create flanges that meet strict industry specifications.

2. Plastic Flange Factories These factories specialize in producing flanges made from various types of plastic, such as PVC, CPVC, and polyethylene. Plastic flanges are often used in chemical plants and water treatment facilities due to their resistance to corrosion and lightweight properties. The manufacturing process for plastic flanges usually involves injection molding or CNC machining.

3. Custom Flange Manufacturers Some flange factories focus on providing customized solutions for unique applications. These manufacturers work closely with clients to develop flanges tailored to specific requirements, including size, shape, and material. This category includes factories that provide flanges for specialized industries such as aerospace, pharmaceuticals, and marine engineering.

Flange Manufacturing Processes

The manufacturing processes employed in flange factories can vary significantly depending on the material and design of the flanges. Here are some common methods used to produce flanges

1. Forging In steel flange factories, the forging process is often used to create flanges. This involves heating a piece of metal and shaping it using dies and hammers. Forged flanges have high strength, making them suitable for high-pressure applications.

2. Machining Many flange manufacturers utilize CNC (Computer Numerical Control) machining to produce precise flanges. This method allows for the creation of complex geometries and tight tolerances. Machined flanges are particularly useful for applications where quality and precision are critical.

type of flange factory

3. Molding In plastic flange factories, molding techniques such as injection molding are commonly used. This process involves injecting molten plastic into a mold to create flanges of various shapes and sizes.

4. Welding Some flanges require welding to attach additional components. Factories equipped with welding capabilities can provide welded flanges that meet specific engineering requirements.

Applications of Flanges

Flanges are used in a wide array of industries, making them essential components in various applications. Some of the key sectors that utilize flanges include

1. Oil and Gas Flanges are vital in the oil and gas industry, where they connect pipelines, valves, and other equipment under high-pressure conditions.

2. Chemical Processing In chemical plants, flanges must withstand corrosive substances. Plastic and stainless steel flanges are frequently used in this sector.

3. Water Treatment Flanges are crucial in water treatment facilities for connecting pipes and valves, ensuring efficient water flow and preventing leaks.

4. Power Generation In power plants, flanges are used to connect turbines, pumps, and other equipment, contributing to the efficient generation of electricity.

Conclusion

Flange factories play a vital role in producing these essential components that support a myriad of industries. By understanding the different types of flange factories, their manufacturing processes, and applications, businesses can make informed decisions when it comes to sourcing flanges for their projects. As industries continue to evolve, the demand for specialized and high-quality flanges will remain a crucial consideration in engineering and manufacturing.

-

In Stock: 1/2" & 3/4" Galvanized Malleable Iron Floor Flanges

NewsAug.04,2025

-

Premium Black & Galvanized Key Clamp Fittings for Furniture Joints | Durable

NewsAug.03,2025

-

Wholesale China Malleable Cast Iron Decorative Floor Flanges

NewsAug.02,2025

-

3/4" Reinforced Bronze Flange Iron Pipe Floor Fitting | Threaded

NewsAug.01,2025

-

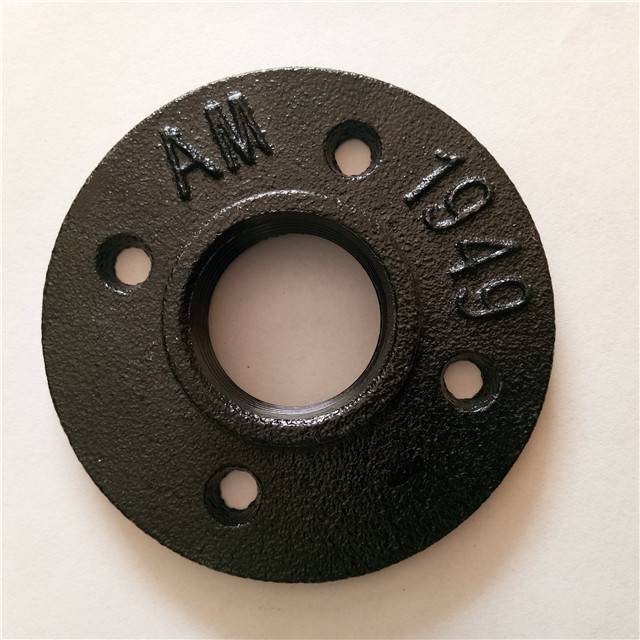

3/4 Inch Black Malleable Iron Floor Flange - Heavy Duty

NewsJul.31,2025

-

Premium Malleable Galvanized Cast Iron Pipe Fittings & Key Clamps

NewsJul.30,2025