-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

nov. . 13, 2024 14:58 Back to list

klamp fitting suppliers

Overview of Klamp Fitting Suppliers

Klamp fittings, often referred to as clamps or couplings, play a crucial role in various industrial applications, ranging from plumbing systems to structural frameworks. As industries increasingly prioritize efficient and robust connection solutions, the demand for quality klamp fitting suppliers has surged. This article aims to explore the key aspects of klamp fittings and highlight what to look for in a reliable supplier.

Understanding Klamp Fittings

Klamp fittings are designed to provide secure connections between pipes, tubes, and other components. These fittings are made from various materials, including stainless steel, carbon steel, and plastic, catering to different environmental conditions and requirements. The versatility of klamp fittings makes them suitable for a wide range of applications, including construction, automotive, and manufacturing sectors.

One of the main advantages of klamp fittings is their ease of installation. Unlike traditional welding or soldering methods, klamp fittings can be assembled quickly and efficiently, thereby minimizing labor costs and downtime. Additionally, they offer the flexibility of disassembly and reusability, which is essential for maintenance and repair tasks.

The Importance of Quality Suppliers

As klamp fittings are integral to system integrity and operational safety, selecting a reputable supplier is paramount. Here are several factors to consider when choosing a klamp fitting supplier

klamp fitting suppliers

1. Product Range A good supplier should offer a wide variety of klamp fittings to cater to different industries and specific application needs. This includes various sizes, materials, and designs to ensure compatibility with existing systems.

2. Quality Assurance Quality is critical when dealing with fittings that must withstand pressure and environmental conditions. Look for suppliers who adhere to industry standards and certifications, such as ISO or ASTM. Reliable suppliers often provide product testing documentation to assure customers of their product's performance.

3. Customization Options Different projects may require bespoke solutions. A supplier that offers customization options can provide fittings tailored to specific dimensions and performance requirements, enhancing overall project efficiency.

4. Customer Support A responsive customer support team can make a significant difference, particularly when dealing with technical inquiries or issues. The best suppliers will offer comprehensive support, including pre-sale advice and post-sale service.

5. Pricing and Availability While quality should never be compromised, pricing is an essential factor for business sustainability. Compare prices among suppliers while keeping an eye on delivery times and stock availability to ensure that you can meet project timelines without incurring extra costs.

Conclusion

In summary, klamp fittings are vital components in various applications that require strong and versatile connections. The selection of a reliable klamp fitting supplier is crucial for ensuring quality, performance, and overall project success. By considering factors such as product range, quality assurance, customization capabilities, customer support, and pricing, businesses can forge partnerships that enhance their operational efficiency and safety. Choosing the right supplier can ultimately lead to improved project outcomes, underscoring the importance of making an informed decision in this area.

-

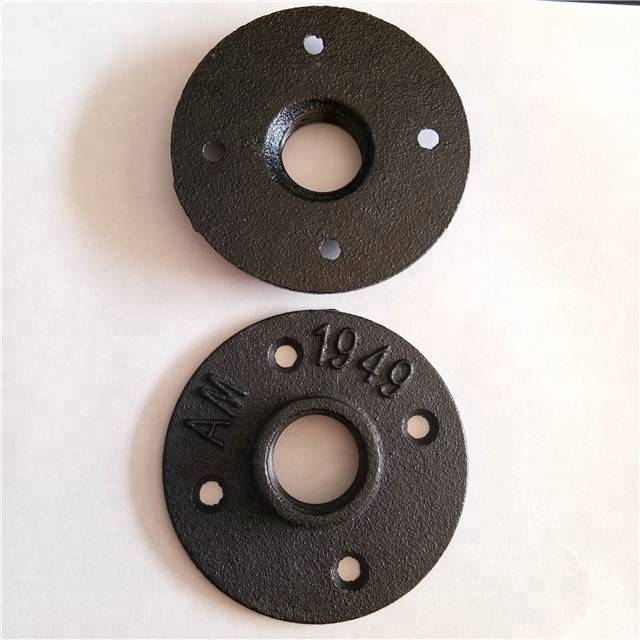

Durable 1/2" 3/4" 1" Iron Threaded Floor Flange Wall Mount Pipe Fitting

NewsAug.25,2025

-

Black Malleable Cast Iron Floor Flange 1/2" BSPT, 3-Hole

NewsAug.22,2025

-

3/4 inch Black Finish Pipe Nipple for Home Decor & DIY

NewsAug.21,2025

-

3/4" Black Malleable Iron Floor Flange - Durable Pipe Fittings

NewsAug.19,2025

-

Durable DN15 1/2" Malleable Iron Threaded Floor Flange

NewsAug.18,2025

-

1/2" Malleable Iron Pipe Fittings for Furniture & Plumbing

NewsAug.17,2025