-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

Nov . 24, 2024 09:35 Back to list

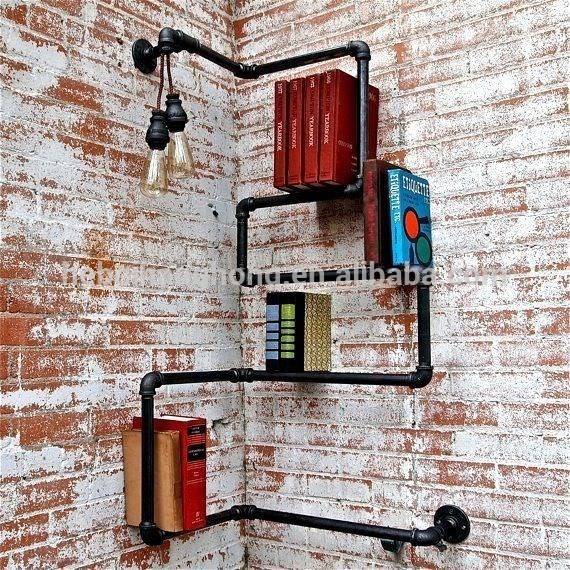

industrial black iron pipe fittings factory

The Significance of Industrial Black Iron Pipe Fittings Factories

In the realm of industrial infrastructure, black iron pipe fittings have become synonymous with strength and reliability. As one of the essential components in plumbing and pipeline installations, these fittings play a crucial role in transporting water, gas, and other essential utilities. The factories that produce these black iron pipe fittings are pivotal in ensuring the quality and availability of these indispensable materials for various industries. This article delves into the significance of these factories, their production processes, and the broader implications for industrial applications.

Understanding Black Iron Pipe Fittings

Black iron pipe fittings are typically made from carbon steel. The term black refers to the uncoated finish of the pipes and fittings, which makes them susceptible to corrosion. However, this characteristic also contributes to their strength and durability, making them ideal for transporting gas and other substances under high pressure. These fittings come in various shapes, including elbows, tees, and couplings, each designed to interconnect sections of piping in a secure and leak-proof manner.

The Role of Factories in Production

Factories specializing in black iron pipe fittings deploy advanced machinery and techniques to ensure the production of high-quality fittings. The manufacturing process begins with the selection of raw materials, which are then subjected to rigorous testing for strength and durability. Following this, the raw materials undergo several stages of processing, including cutting, molding, and welding. Factories utilize various methodologies, such as precision casting and forging, to produce fittings that meet specific industry standards and customer requirements.

Quality control is an integral part of the manufacturing process. As adherence to safety standards is paramount in industrial applications, factories implement stringent testing protocols. Each finished product is subjected to pressure tests, visual inspections, and dimensional checks to guarantee that they meet or exceed industry specifications. This meticulous attention to detail not only ensures the safety of installations but also enhances the overall reputation of manufacturers in the marketplace.

Economic Implications

industrial black iron pipe fittings factory

The black iron pipe fittings industry is significant in terms of economic contributions. Factories generate employment opportunities, providing jobs for skilled and unskilled workers alike. From machine operators to quality inspectors, a wide range of roles is essential for the successful operation of these factories. Additionally, these workplaces often stimulate local economies by sourcing materials and services from nearby suppliers, further supporting the community.

Moreover, the demand for industrial black iron pipe fittings is tied closely to broader economic trends. As construction projects and infrastructural development accelerate, the need for reliable piping systems increases. This correlation has led to steady growth within the industry, encouraging factories to innovate and adapt to emerging market demands. Sustainable practices are also becoming increasingly important, prompting manufacturers to explore eco-friendly options in their production processes.

Innovations in Manufacturing and Design

In response to the dynamic needs of the market, black iron pipe fittings factories are embracing innovative technologies. Automation has transformed traditional manufacturing processes, increasing efficiency and reducing costs. Computer numerical control (CNC) machining, for instance, allows for precise fabrication of components, minimizing material waste and enhancing design capabilities.

Furthermore, advancements in coatings and finishes are improving the longevity and corrosion resistance of these fittings. Manufacturers are now incorporating protective layers and coatings that extend the lifespan and performance of black iron pipe fittings, thus addressing some of the inherent challenges associated with non-coated products.

Conclusion

The factories that produce industrial black iron pipe fittings are more than mere production facilities—they are vital contributors to the infrastructure of modern society. Through their commitment to quality, economic growth, and innovation, these factories ensure that robust and reliable piping systems are available for various industrial applications. As industries continue to evolve, these factories will play a crucial role in adapting to new technologies and maintaining the standards required for safety and efficiency. The importance of black iron pipe fittings in transportation, construction, and various other sectors underscores the critical need for ongoing investments in manufacturing capabilities and quality assurance. In essence, the future of industrial black iron pipe fittings will continue to shape the landscape of infrastructure and economic development for years to come.

-

Durable DN15 1/2" Malleable Iron Threaded Floor Flange

NewsAug.18,2025

-

1/2" Malleable Iron Pipe Fittings for Furniture & Plumbing

NewsAug.17,2025

-

Urban 3/4" Floor Flange for DIY RH Inspired Shelving

NewsAug.16,2025

-

Vintage Galvanized Pipe Chandelier - Industrial Lighting

NewsAug.15,2025

-

Industrial Pipe Shelf Brackets 'T' - Heavy 3/4" Iron

NewsAug.14,2025

-

Durable 2" Black Malleable Iron Pipe & 3/4" Threaded Fittings

NewsAug.13,2025