-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

Aug . 30, 2024 12:39 Back to list

High-Quality Table E Flange Manufacturers | Precision Engineering Solutions

Understanding Table E Flange Factories A Key Component in Industrial Manufacturing

Table E flanges are an essential component in various industries, serving crucial functions in piping and structural systems. These flanges, which are typically made of materials like carbon steel, stainless steel, or alloy, are designed to join two sections of pipe or other equipment together securely. The production of Table E flanges is a specialized process, often handled by dedicated factories that focus on manufacturing these key elements with precision and quality.

Understanding Table E Flange Factories A Key Component in Industrial Manufacturing

The manufacturing process of Table E flanges involves several critical steps. First, the raw materials are sourced and inspected to ensure they meet the required specifications. Factories utilize advanced technologies, such as CNC machining and laser cutting, to achieve the precise dimensions required for Table E flanges. Once the raw materials are cut to size, they undergo processes like forging, welding, and heat treatment to enhance their strength and durability.

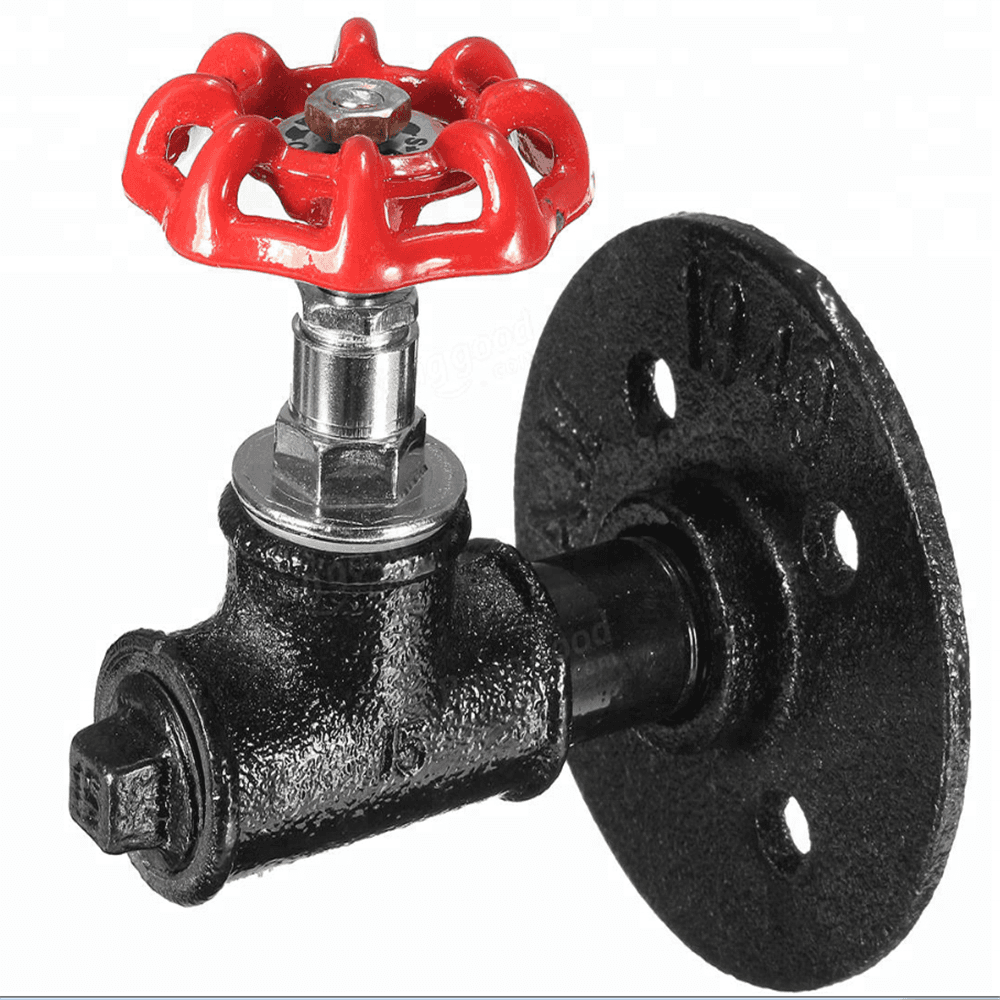

table e flange factories

Quality control is paramount in flange manufacturing. Reputable factories implement rigorous inspection processes at every stage of production. This includes testing the physical and chemical properties of the flanges, as well as conducting pressure tests to ensure they meet safety standards. Non-destructive testing techniques, such as ultrasonic and radiographic inspections, are also employed to detect any potential defects that could compromise the integrity of the flanges during operation.

Furthermore, these factories are increasingly focusing on sustainability and environmental responsibility. Many are investing in energy-efficient machinery and practices, as well as techniques to minimize waste during the production process. This aligns with the growing demand for eco-friendly products in the industrial sector, allowing companies to meet regulatory requirements and bolster their reputation among environmentally-conscious consumers.

In recent years, the global demand for Table E flanges has seen significant growth, driven by expansion in various sectors such as construction, energy, and transportation. As industries evolve and the need for reliable infrastructure increases, the role of flange manufacturers becomes even more critical. They must not only produce high-quality products but also adapt to changing market trends and technological advancements.

In conclusion, Table E flange factories play a vital role in the industrial landscape by providing essential components for a multitude of applications. Their commitment to quality, efficiency, and sustainability is fundamental to the success of the industries they serve. As globalization continues to influence manufacturing practices, these factories must remain agile, ensuring they meet the demands of an ever-changing market while maintaining the highest standards of product integrity. By understanding the intricacies of flange production and the challenges faced by these factories, we can appreciate the significant impact they have on modern industrial operations.

-

Heavy Duty 3/4" Industrial Pipe 'T' Shelf Brackets - Dark Grey Iron

NewsAug.27,2025

-

Black Floor Flange 1/2 for Furniture | Industrial Pipe Decor DIY

NewsAug.26,2025

-

Durable 1/2" 3/4" 1" Iron Threaded Floor Flange Wall Mount Pipe Fitting

NewsAug.25,2025

-

Black Malleable Cast Iron Floor Flange 1/2" BSPT, 3-Hole

NewsAug.22,2025

-

3/4 inch Black Finish Pipe Nipple for Home Decor & DIY

NewsAug.21,2025

-

3/4" Black Malleable Iron Floor Flange - Durable Pipe Fittings

NewsAug.19,2025