-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

Aug . 21, 2024 10:18 Back to list

Manufacturers of DN15 Floor Flanges for Reliable and Durable Connections

Understanding Floor Flange DN15 Manufacturers

When it comes to plumbing and piping systems, the importance of reliable connections cannot be overstated. One of the key components used to achieve this is the floor flange, particularly the DN15 size. Floor flanges are integral parts of various piping systems and are essential for providing stability and robustness. In this article, we will delve into the role of DN15 floor flanges and what manufacturers must consider in their production to ensure high-quality products.

What is a Floor Flange?

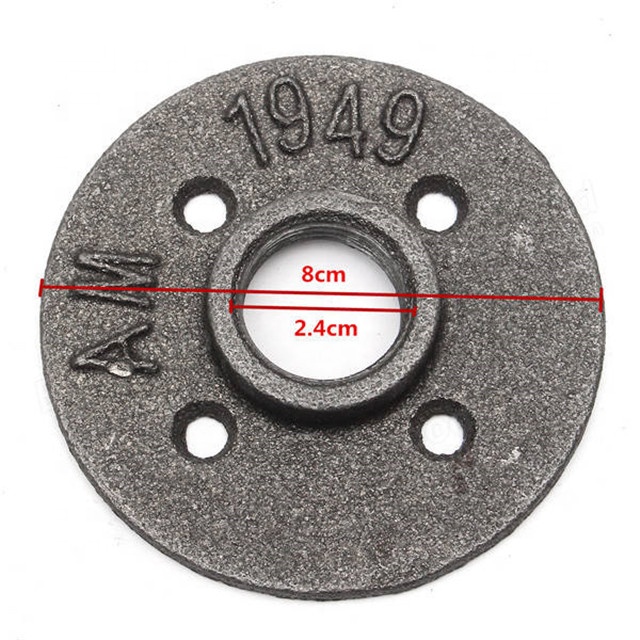

A floor flange is a disc-shaped component made from metal or plastic, used to connect piping systems to a floor or other surfaces. They provide a stable base or support for the piping, allowing for greater load-bearing capabilities and reducing the risk of wear and tear. The DN stands for Diameter Nominal, which refers to the nominal pipe size. DN15, specifically, corresponds to a pipe size of 15 millimeters in diameter.

The Importance of Quality Manufacturing

Manufacturers of floor flanges, especially DN15 variants, must adhere to strict quality standards to ensure the safety and efficiency of their products. This includes using high-grade materials that can withstand various environmental conditions such as temperature fluctuations, humidity, and pressure changes. Common materials used in the production of floor flanges include stainless steel, carbon steel, and PVC, each chosen for its particular properties.

The manufacturing process itself also plays a crucial role in the final quality of the floor flange. Techniques such as forging and machining must be executed with precision to avoid defects that could result in leaks or pipe failures. Given the critical nature of these components in plumbing systems, manufacturers often undergo rigorous testing to validate their products' strength, durability, and compatibility with other pipeline components.

Customization and Standardization

floor flange dn15 manufacturers

In addition to mass-producing standard DN15 floor flanges, many manufacturers offer customization options to meet specific customer needs. This can include variations in material, coating options, or design adjustments that accommodate unique installation requirements. Customization is particularly useful in specialized industries, such as oil and gas or chemical processing, where standard components may not suffice.

However, while customization is valuable, there is also a need for standardization in the industry. Standardized floor flanges ensure compatibility across various systems and simplify installation and maintenance processes. Manufacturers must balance the demand for bespoke solutions with adherence to industry standards, such as those set by the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO).

The Role of Innovation

Innovation plays a significant role in the competitive landscape of floor flange manufacturing. As technologies advance, manufacturers are increasingly adopting modern techniques like 3D printing and computer-aided design (CAD) in their production processes. These methods can lead to reduced lead times, minimized waste, and enhanced design capabilities, allowing manufacturers to offer more versatile and affordable solutions to their customers.

Moreover, environmental considerations are becoming more prominent in manufacturing practices. Sustainable materials and eco-friendly production processes not only help reduce the carbon footprint but also attract environmentally conscious clients. Manufacturers who embrace sustainability are likely to gain a competitive edge in the marketplace.

Conclusion

In conclusion, floor flanges, and specifically DN15 sizes, are essential components in plumbing and piping systems. Manufacturers in this field must prioritize quality, adhere to industry standards, and embrace innovation to stay competitive. Given the growing demand for reliable piping solutions, the importance of skilled manufacturers cannot be underestimated. As the industry continues to evolve, those who adapt to changing needs and technologies will continue to lead and excel in the market.

-

4X 3/4 Malleable Iron Pipe Fittings Floor Flange 3/4" Threaded BSP Wall Mount

NewsMar.07,2025

-

Galvanized 24yy 3/4"flange key clamp used for 26.9mm pipe

NewsMar.07,2025

-

3/4inch malleable cast iron design plumbing pipe rustic industrial pipe shelf

NewsMar.07,2025

-

3/4'' black iron floor flange for plumbing pipe table

NewsMar.07,2025

-

Malleable Iron Pipe Floor Threaded Fitting Black Flange

NewsMar.07,2025

-

china brass pipe fittings

NewsMar.07,2025