-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

Jun . 15, 2024 18:14 Back to list

Manufacturers of cast iron pipe fittings and flanges

Exploring the World of Pipe Fittings, Cast Iron Flanges A Journey through Leading Factories

In the realm of industrial infrastructure and plumbing systems, pipe fittings and cast iron flanges play a pivotal role. These components, often unseen but critically important, ensure the seamless flow of fluids and gases in various sectors, from oil and gas to water supply and waste management. Among the myriad of materials used, cast iron flanges have stood the test of time due to their durability and resistance to corrosion. This article delves into the heart of factories that specialize in manufacturing these essential elements.

Cast iron, with its robust composition, has been a staple in pipe fitting production for centuries. It is in these specialized factories where raw materials transform into functional flanges, connecting pipes and ensuring secure joints. Factories such as those in China, India, and the United States are renowned for their expertise in this field.

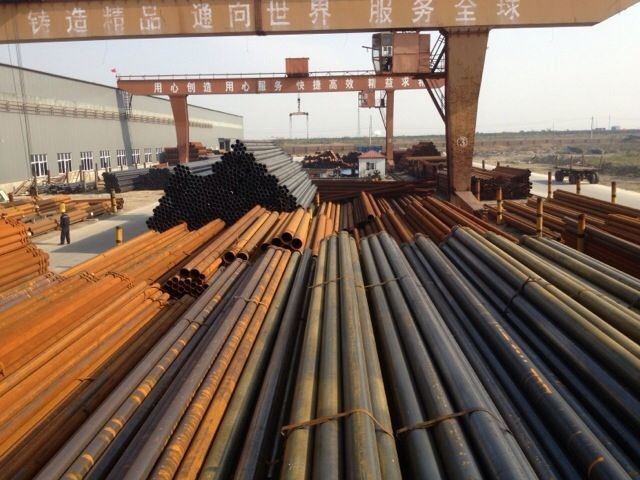

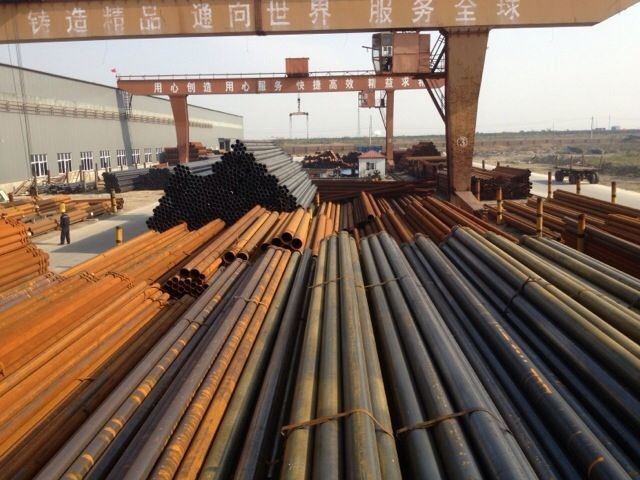

Chinese factories, particularly in the Zhejiang and Hebei provinces, are global leaders in pipe fittings and cast iron flange production. They boast state-of-the-art facilities and advanced machinery, enabling them to produce large quantities with precision and efficiency. Their strict adherence to international standards like ANSI, ASME, and DIN ensures the quality of their products.

On the other hand, Indian factories, especially in cities like Ahmedabad and Mumbai, offer cost-effective solutions without compromising on quality. Their skilled workforce, combined with traditional casting techniques and modern technology, creates a unique blend of craftsmanship and innovation Their skilled workforce, combined with traditional casting techniques and modern technology, creates a unique blend of craftsmanship and innovation Their skilled workforce, combined with traditional casting techniques and modern technology, creates a unique blend of craftsmanship and innovation Their skilled workforce, combined with traditional casting techniques and modern technology, creates a unique blend of craftsmanship and innovation

Their skilled workforce, combined with traditional casting techniques and modern technology, creates a unique blend of craftsmanship and innovation Their skilled workforce, combined with traditional casting techniques and modern technology, creates a unique blend of craftsmanship and innovation pipe fittings cast iron flange factories.

In the United States, factories like those in the Rust Belt region have a long history in iron casting. Their focus on customization and adherence to stringent safety regulations make their flanges highly sought after in industries requiring heavy-duty applications.

Each of these factories operates with a commitment to sustainability, recycling scrap metal and implementing eco-friendly practices. They also invest heavily in research and development to improve product design and reduce environmental impact.

The production process begins with melting iron ore in blast furnaces, followed by molding and casting into the desired flange shape. Quality control measures,,。 Afterward, the flanges undergo heat treatment to enhance their strength and durability, before being coated to prevent rusting.

In conclusion, the world of pipe fittings and cast iron flange factories is a testament to human ingenuity and industrial prowess. These factories, scattered across the globe, are not just manufacturers but also contributors to global infrastructure, ensuring the smooth functioning of countless systems that support our daily lives. As technology advances and environmental concerns escalate, these factories continue to evolve, adapting to new challenges and setting benchmarks for the industry.

pipe fittings cast iron flange factories.

In the United States, factories like those in the Rust Belt region have a long history in iron casting. Their focus on customization and adherence to stringent safety regulations make their flanges highly sought after in industries requiring heavy-duty applications.

Each of these factories operates with a commitment to sustainability, recycling scrap metal and implementing eco-friendly practices. They also invest heavily in research and development to improve product design and reduce environmental impact.

The production process begins with melting iron ore in blast furnaces, followed by molding and casting into the desired flange shape. Quality control measures,,。 Afterward, the flanges undergo heat treatment to enhance their strength and durability, before being coated to prevent rusting.

In conclusion, the world of pipe fittings and cast iron flange factories is a testament to human ingenuity and industrial prowess. These factories, scattered across the globe, are not just manufacturers but also contributors to global infrastructure, ensuring the smooth functioning of countless systems that support our daily lives. As technology advances and environmental concerns escalate, these factories continue to evolve, adapting to new challenges and setting benchmarks for the industry.

Their skilled workforce, combined with traditional casting techniques and modern technology, creates a unique blend of craftsmanship and innovation Their skilled workforce, combined with traditional casting techniques and modern technology, creates a unique blend of craftsmanship and innovation

Their skilled workforce, combined with traditional casting techniques and modern technology, creates a unique blend of craftsmanship and innovation Their skilled workforce, combined with traditional casting techniques and modern technology, creates a unique blend of craftsmanship and innovation pipe fittings cast iron flange factories.

In the United States, factories like those in the Rust Belt region have a long history in iron casting. Their focus on customization and adherence to stringent safety regulations make their flanges highly sought after in industries requiring heavy-duty applications.

Each of these factories operates with a commitment to sustainability, recycling scrap metal and implementing eco-friendly practices. They also invest heavily in research and development to improve product design and reduce environmental impact.

The production process begins with melting iron ore in blast furnaces, followed by molding and casting into the desired flange shape. Quality control measures,,。 Afterward, the flanges undergo heat treatment to enhance their strength and durability, before being coated to prevent rusting.

In conclusion, the world of pipe fittings and cast iron flange factories is a testament to human ingenuity and industrial prowess. These factories, scattered across the globe, are not just manufacturers but also contributors to global infrastructure, ensuring the smooth functioning of countless systems that support our daily lives. As technology advances and environmental concerns escalate, these factories continue to evolve, adapting to new challenges and setting benchmarks for the industry.

pipe fittings cast iron flange factories.

In the United States, factories like those in the Rust Belt region have a long history in iron casting. Their focus on customization and adherence to stringent safety regulations make their flanges highly sought after in industries requiring heavy-duty applications.

Each of these factories operates with a commitment to sustainability, recycling scrap metal and implementing eco-friendly practices. They also invest heavily in research and development to improve product design and reduce environmental impact.

The production process begins with melting iron ore in blast furnaces, followed by molding and casting into the desired flange shape. Quality control measures,,。 Afterward, the flanges undergo heat treatment to enhance their strength and durability, before being coated to prevent rusting.

In conclusion, the world of pipe fittings and cast iron flange factories is a testament to human ingenuity and industrial prowess. These factories, scattered across the globe, are not just manufacturers but also contributors to global infrastructure, ensuring the smooth functioning of countless systems that support our daily lives. As technology advances and environmental concerns escalate, these factories continue to evolve, adapting to new challenges and setting benchmarks for the industry. Share

Latest news

-

4X 3/4 Malleable Iron Pipe Fittings Floor Flange 3/4" Threaded BSP Wall Mount

NewsMar.07,2025

-

Galvanized 24yy 3/4"flange key clamp used for 26.9mm pipe

NewsMar.07,2025

-

3/4inch malleable cast iron design plumbing pipe rustic industrial pipe shelf

NewsMar.07,2025

-

3/4'' black iron floor flange for plumbing pipe table

NewsMar.07,2025

-

Malleable Iron Pipe Floor Threaded Fitting Black Flange

NewsMar.07,2025

-

china brass pipe fittings

NewsMar.07,2025

PRODUCTS