-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

Aug . 21, 2024 04:50 Back to list

BSP Screwed Flange Manufacturers and Their Key Features and Benefits

The Rise of BSP Screwed Flange Factories An Overview

In recent years, the demand for high-quality piping components has surged globally, particularly in the oil and gas, petrochemical, and construction industries. Among these critical components, BSP (British Standard Pipe) screwed flanges have gained significant attention for their ease of installation, versatility, and reliability. This article explores the essential role of BSP screwed flange factories in fulfilling the growing market demand and the implications for industry standards and practices.

Understanding BSP Screwed Flanges

BSP screwed flanges are designed to connect pipes without the need for welding, making them an ideal choice in situations where welding might be impractical or undesirable. These flanges feature threads that allow them to be screwed onto the ends of pipes, ensuring a tight seal that prevents leaks. The simplicity of this design enables quick and efficient assembly, which is particularly valuable in time-sensitive projects.

Moreover, BSP flanges come in various sizes and pressure ratings, making them suitable for different applications, from residential plumbing systems to large industrial pipelines. The compatibility of BSP flanges with other BSP fittings also enhances their popularity, allowing for more seamless integration into existing systems.

The Role of Factories in Production

As demand for BSP screwed flanges continues to rise, factories specializing in their production have become increasingly essential. These factories utilize advanced manufacturing processes and state-of-the-art machinery to produce flanges that meet stringent quality standards. The emphasis on precision and quality control ensures that the flanges perform reliably under various operating conditions.

Moreover, many factories are adopting innovative technologies, such as automation and computer-aided design (CAD), which enhance the efficiency of production processes. By streamlining operations, these factories can respond more quickly to market demands, reducing lead times and improving customer satisfaction.

bsp screwed flange factories

Meeting Industry Standards

BSP screwed flange factories often adhere to international quality and safety standards, such as ISO 9001 and ASME standards. Compliance with these standards is crucial for maintaining product integrity and ensuring that the flanges can withstand the rigors of various applications. Factory certifications serve as a testament to the quality of their products, providing customers with confidence in their purchases.

In addition to adhering to standard specifications, many factories are also investing in research and development to innovate and improve flange designs. This proactive approach not only enhances the performance of flanges but also aligns with the industry's shift towards sustainability by developing materials and processes that minimize environmental impact.

Challenges Faced by Manufacturers

Despite the positive outlook for BSP screwed flange factories, they face several challenges in the current market landscape. Increased competition from both domestic and international manufacturers has put pressure on factories to maintain competitive pricing while ensuring high quality. Additionally, fluctuations in raw material prices can impact production costs, requiring manufacturers to adapt quickly to changing market conditions.

Supply chain disruptions, especially in the wake of global events like the COVID-19 pandemic, have also posed challenges. Factories must develop more resilient supply chains to ensure uninterrupted production and delivery of their products.

Conclusion

BSP screwed flange factories are at the forefront of meeting the rising demand for reliable piping components in various industries. Their commitment to quality, efficiency, and innovation positions them as pivotal players in the manufacturing landscape. As technology advances and market needs evolve, these factories will continue to adapt, ensuring that they provide high-quality BSP flanges that are integral to modern infrastructure. Ultimately, their role will be crucial in supporting the infrastructure of tomorrow while navigating the challenges of a dynamic and competitive environment.

-

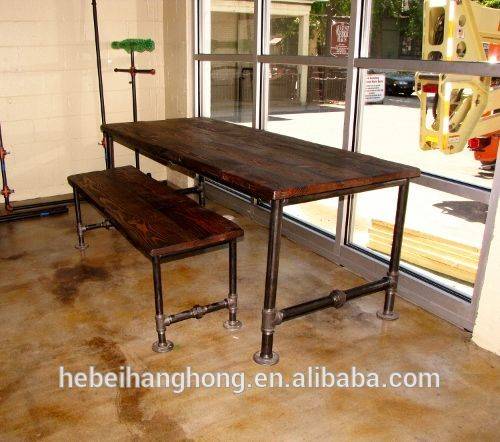

Black Floor Flange 1/2 for Furniture | Industrial Pipe Decor DIY

NewsAug.26,2025

-

Durable 1/2" 3/4" 1" Iron Threaded Floor Flange Wall Mount Pipe Fitting

NewsAug.25,2025

-

Black Malleable Cast Iron Floor Flange 1/2" BSPT, 3-Hole

NewsAug.22,2025

-

3/4 inch Black Finish Pipe Nipple for Home Decor & DIY

NewsAug.21,2025

-

3/4" Black Malleable Iron Floor Flange - Durable Pipe Fittings

NewsAug.19,2025

-

Durable DN15 1/2" Malleable Iron Threaded Floor Flange

NewsAug.18,2025