-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

11-р сар . 02, 2024 02:54 Back to list

nipple pipe fitting factory

Nipple Pipe Fitting Factory An Essential Component in Industrial Plumbing

In the world of industrial plumbing, the significance of high-quality components cannot be overstated. Among these components, nipple pipe fittings play a pivotal role in establishing secure and efficient plumbing systems. A nipple pipe fitting factory focuses on manufacturing these crucial elements, catering to various industries that require durable and reliable plumbing solutions.

Nipple pipe fittings are typically short pieces of pipe, threaded at both ends, that are designed to connect two other fittings or pipes. Their utility spans across various applications, including water supply systems, gas lines, and chemical processing, making them a versatile choice for contractors and engineers alike. The factory that specializes in producing these fittings must adhere to strict quality control measures to ensure that every fitting meets industry standards.

At the heart of a nipple pipe fitting factory is its manufacturing process

. The journey begins with high-grade raw materials, usually steel, brass, or plastic, chosen for their strength and resistance to corrosion. The manufacturing process involves cutting the raw materials into the desired lengths and crafting threads on both ends, which allows for easy connection to other fittings or pipes. Advanced machining tools and technology are utilized to ensure precision and consistency in every piece that comes off the production line.nipple pipe fitting factory

Quality assurance is crucial in the nipple pipe fitting industry. Factories often implement rigorous testing procedures, such as pressure testing and dimensional inspections, to identify any defects before the products leave the facility. This not only guarantees the reliability of the fittings but also instills confidence in contractors who rely on these components for their projects.

Sustainability is also becoming a significant consideration for modern nipple pipe fitting factories. Many manufacturers are now exploring eco-friendly practices, such as using recyclable materials and reducing waste during the production process. This shift reflects the growing demand for environmentally conscious products in the plumbing sector, ultimately benefiting both clients and the planet.

One of the advantages of working with a specialized nipple pipe fitting factory is the potential for custom solutions. Many factories offer tailored products to meet specific project requirements, allowing for greater flexibility in design and function. This customization ensures that every client receives fittings that are perfectly suited for their unique applications.

In conclusion, a nipple pipe fitting factory is an integral part of the plumbing supply chain, providing essential components that support a wide range of industrial applications. With a focus on quality, precision, and sustainability, these factories not only meet the demands of today’s market but also look towards a more responsible future. As industries continue to evolve, the role of nipple pipe fittings will undoubtedly remain crucial in ensuring efficient and reliable plumbing systems worldwide.

-

Premium NPT Threaded Fittings Hot Sell | Trusted Alibaba Assessed Supplier

NewsJul.21,2025

-

Product Name

NewsJul.21,2025

-

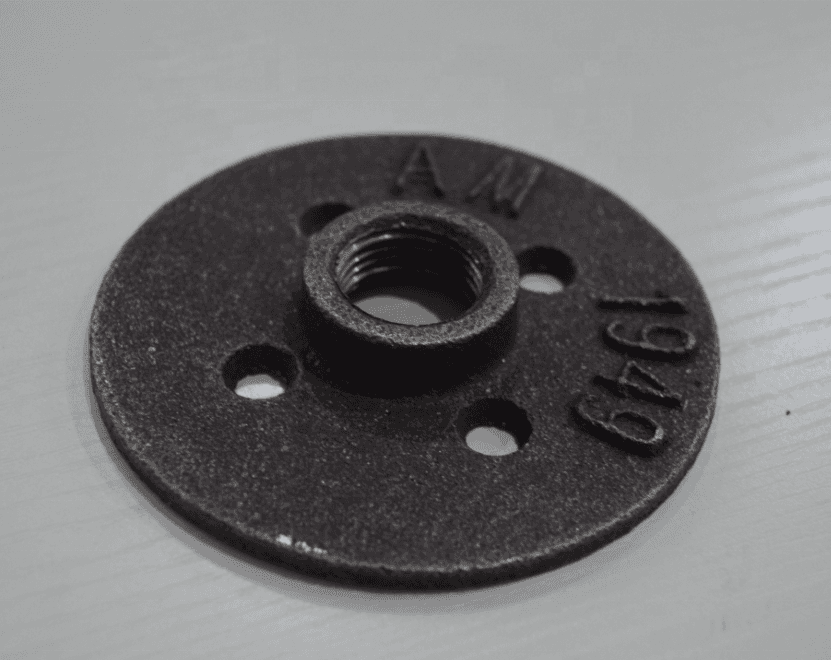

4X 3/4 Malleable Iron Pipe Fittings Floor Flange 3/4" Threaded BSP Wall Mount

NewsMar.07,2025

-

Galvanized 24yy 3/4"flange key clamp used for 26.9mm pipe

NewsMar.07,2025

-

3/4inch malleable cast iron design plumbing pipe rustic industrial pipe shelf

NewsMar.07,2025

-

3/4'' black iron floor flange for plumbing pipe table

NewsMar.07,2025