-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

9-р сар . 25, 2024 14:52 Back to list

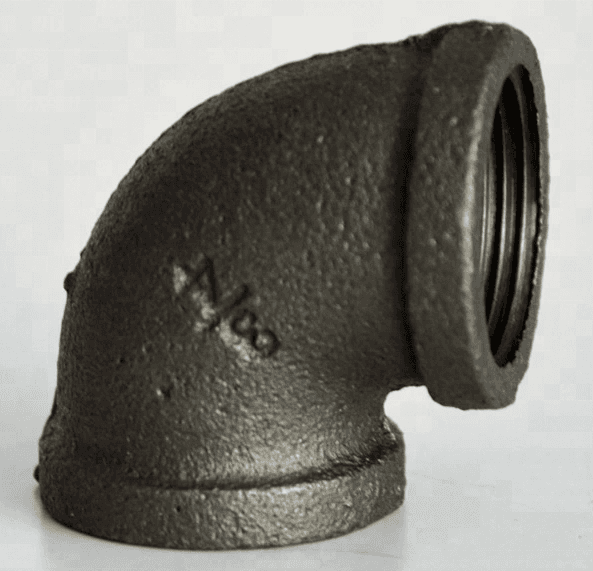

malleable pipes factory

The Innovation and Impact of Malleable Pipes in Modern Industries

Malleable pipes have become an integral part of various industrial applications due to their impressive flexibility, strength, and durability. As industries evolve, the demand for versatile piping solutions increases, placing malleable pipe factories at the forefront of manufacturing advancements. This article explores the significance of malleable pipes, the manufacturing processes involved in their production, and the diverse applications across different sectors.

Understanding Malleable Pipes

Malleable pipes are typically made from cast iron and are designed to withstand considerable stress while offering the flexibility needed for various formations. Unlike traditional rigid pipes, malleable pipes can be bent and shaped into different configurations without collapsing or breaking. This quality makes them ideal for a range of applications, from plumbing systems to gas and oil transport.

The malleable nature of these pipes stems from the unique alloys used in their production and the specific manufacturing techniques employed. The ability to mold these pipes into various shapes allows for more efficient transport and installation, reducing the need for numerous fittings and joints, ultimately saving time and reducing overall costs.

Manufacturing Process

The process of manufacturing malleable pipes begins with the selection of high-quality raw materials, primarily iron. The production process involves several key steps

1. Casting The initial step involves casting iron into a specific shape using molds. This creates the basic form of the pipe. 2. Heat Treatment The cast iron undergoes a heat treatment process, which enhances its malleability. This step is crucial, as it prepares the material for subsequent shaping and bending processes.

3. Machining Once heat-treated, the pipes are machined to precise dimensions. This includes drilling or threading to create the necessary connections for fittings.

4. Quality Control Rigorous testing and quality control measures are taken to ensure the pipes meet industry standards. This includes tensile strength tests and inspections for defects.

5. Finishing Finally, the pipes go through a finishing process that may involve coating with protective materials to enhance resistance to corrosion and wear, ultimately improving their longevity.

malleable pipes factory

These manufacturing processes, combined with technological advancements, ensure that malleable pipes produced in modern factories not only meet stringent quality standards but also cater to the evolving needs of various industries

.Diverse Applications

Malleable pipes find applications across multiple sectors, showcasing their versatility and advantages

- Plumbing Systems In residential and commercial plumbing, malleable pipes are favored for their ability to be easily bent around corners and obstacles, providing efficient water supply solutions with minimal leakage.

- Gas Distribution Malleable pipes are commonly used for natural gas and propane distribution due to their ability to withstand high pressures and resist explosive ruptures, ensuring safety in gas installation.

- Oil Transport In the oil industry, these pipes play a critical role in transferring crude oil and its derivatives, as their durability prevents leaks and environmental hazards.

- Agricultural Applications Malleable pipes are also utilized in agriculture for irrigation systems, providing farmers with durable solutions that can adapt to varying field shapes and require minimal maintenance.

- Construction and Infrastructure Malleable pipes are used in the construction of buildings for heating and cooling systems, allowing for efficient airflow while being easy to install in complex architectural designs.

Conclusion

Malleable pipes represent a significant innovation in piping solutions, with factories producing these versatile products playing a vital role in supporting numerous industries. The manufacturing processes behind malleable pipes demonstrate a unique combination of traditional craftsmanship and modern technology, ensuring high-quality outputs. As industries continue to seek more flexible and efficient solutions, the relevance of malleable pipes is likely to grow, leading to further advancements in their design and application. The future of malleable pipe production holds great promise, with ongoing research and development likely to enhance their usability and sustainability, making them indispensable components in modern engineering and infrastructure.

-

3/4" Black Malleable Iron Floor Flange - Durable Pipe Fittings

NewsAug.19,2025

-

Durable DN15 1/2" Malleable Iron Threaded Floor Flange

NewsAug.18,2025

-

1/2" Malleable Iron Pipe Fittings for Furniture & Plumbing

NewsAug.17,2025

-

Urban 3/4" Floor Flange for DIY RH Inspired Shelving

NewsAug.16,2025

-

Vintage Galvanized Pipe Chandelier - Industrial Lighting

NewsAug.15,2025

-

Industrial Pipe Shelf Brackets 'T' - Heavy 3/4" Iron

NewsAug.14,2025