-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

ജനു . 20, 2025 15:19 Back to list

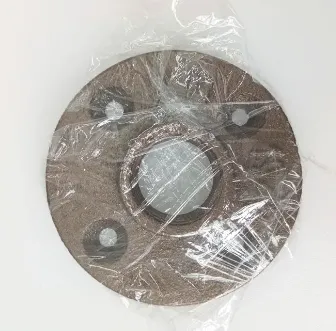

high quality cast iron pipe flanges,galvanized malleable iron pipe flanges

Navigating the expansive world of wholesale iron pipe fittings can feel like a complex puzzle, yet understanding the various types and their applications can significantly enhance your procurement strategy. Iron pipe fittings play a crucial role across diverse industries, from construction to agriculture, owing to their durability and reliability. Here is a comprehensive guide to the most prominent types, shedding light on their unique features and best use cases.

Reducers are crucial for adjusting the flow rate within a pipeline system. By connecting pipes of varying diameters, they regulate flow while mitigating pressure changes that can lead to system inefficiencies or potential damage. Concentric reducers align the centerlines of pipes, optimizing smooth flow during reductions, whereas eccentric reducers are preferred for preventing air accumulation in horizontal pipes. 6. Unions Enabling Convenient Assembly and Disassembly Unions offer the ease of connecting two pipes without rotation, essential in systems requiring frequent maintenance. Comprising three parts – a nut, a male end, and a female end – they accommodate easy assembly and disassembly, effectively balancing convenience with structural integrity. For systems subjected to regular changes or motions, iron unions provide a robust solution, minimizing downtime and operational disruptions. 7. Caps and Plugs Sealing with Assurance Caps and plugs are pivotal for effectively sealing pipe ends. Whether the system is temporarily inactive, under maintenance, or permanently closed, these fittings provide a secure barrier against contaminants and leaks. Iron caps and plugs, available in various configurations, are chosen for their robustness in sealing high-pressure systems, ensuring safety and conserving the integrity of the entire pipeline. Professional Insights Navigating the market for wholesale iron pipe fittings requires not only knowledge of specific types but also an understanding of material compatibility, pressure ratings, and installation requirements. Trustworthy suppliers prioritize quality and compliance with international standards, offering warranties that attest to their product reliability. An expert approach ensures the components not only fit the system requirements but also enhance performance and extend the longevity of the installations. For industries where pipeline integrity directly impacts safety and efficiency, the selection of the appropriate iron pipe fittings is paramount. Embracing a strategy that includes robust sourcing practices, backed by technological advances in manufacturing and a deep understanding of application-specific needs, stakeholders can optimize operational performance and cost-effectiveness. This extensive guide on wholesale iron pipe fitting types not only elucidates the distinct functionalities each fitting offers but also reinforces the tangible benefits of making informed decisions based on expertise, authority, and trustworthiness in procurement practices.

Reducers are crucial for adjusting the flow rate within a pipeline system. By connecting pipes of varying diameters, they regulate flow while mitigating pressure changes that can lead to system inefficiencies or potential damage. Concentric reducers align the centerlines of pipes, optimizing smooth flow during reductions, whereas eccentric reducers are preferred for preventing air accumulation in horizontal pipes. 6. Unions Enabling Convenient Assembly and Disassembly Unions offer the ease of connecting two pipes without rotation, essential in systems requiring frequent maintenance. Comprising three parts – a nut, a male end, and a female end – they accommodate easy assembly and disassembly, effectively balancing convenience with structural integrity. For systems subjected to regular changes or motions, iron unions provide a robust solution, minimizing downtime and operational disruptions. 7. Caps and Plugs Sealing with Assurance Caps and plugs are pivotal for effectively sealing pipe ends. Whether the system is temporarily inactive, under maintenance, or permanently closed, these fittings provide a secure barrier against contaminants and leaks. Iron caps and plugs, available in various configurations, are chosen for their robustness in sealing high-pressure systems, ensuring safety and conserving the integrity of the entire pipeline. Professional Insights Navigating the market for wholesale iron pipe fittings requires not only knowledge of specific types but also an understanding of material compatibility, pressure ratings, and installation requirements. Trustworthy suppliers prioritize quality and compliance with international standards, offering warranties that attest to their product reliability. An expert approach ensures the components not only fit the system requirements but also enhance performance and extend the longevity of the installations. For industries where pipeline integrity directly impacts safety and efficiency, the selection of the appropriate iron pipe fittings is paramount. Embracing a strategy that includes robust sourcing practices, backed by technological advances in manufacturing and a deep understanding of application-specific needs, stakeholders can optimize operational performance and cost-effectiveness. This extensive guide on wholesale iron pipe fitting types not only elucidates the distinct functionalities each fitting offers but also reinforces the tangible benefits of making informed decisions based on expertise, authority, and trustworthiness in procurement practices.

Share

Next:

Latest news

-

Black Malleable Cast Iron Floor Flange 1/2" BSPT, 3-Hole

NewsAug.22,2025

-

3/4 inch Black Finish Pipe Nipple for Home Decor & DIY

NewsAug.21,2025

-

3/4" Black Malleable Iron Floor Flange - Durable Pipe Fittings

NewsAug.19,2025

-

Durable DN15 1/2" Malleable Iron Threaded Floor Flange

NewsAug.18,2025

-

1/2" Malleable Iron Pipe Fittings for Furniture & Plumbing

NewsAug.17,2025

-

Urban 3/4" Floor Flange for DIY RH Inspired Shelving

NewsAug.16,2025

PRODUCTS