-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

Ное . 28, 2024 03:38 Back to list

High-Quality Steel Tee Manufacturing for Various Industrial Applications

The Steel Tee Factory A Pillar of Industrial Strength

In the realm of construction and manufacturing, steel components play a critical role in ensuring structural integrity and durability. Among the various steel products, the steel tee is a fundamental shape that finds application in diverse industries, from civil engineering to machinery fabrication. Understanding the operations and significance of a steel tee factory provides insight into the backbone of industrial infrastructure.

The Significance of Steel Tee

A steel tee, characterized by its T-shaped cross-section, is essential in providing support and stability in various constructions. The design allows for ease of connection with other steel components, making it a preferred choice in building frames, bridges, and support structures. Its ability to resist bending and twisting under loads makes it invaluable, not just for construction, but also in the manufacturing of machinery where strength and reliability are paramount.

Manufacturing Process

The journey of a steel tee from raw material to finished product begins at a steel mill. The primary raw material used is steel, which can be sourced in various forms, including recycled steel. The steel is first melted in electric arc furnaces, where it reaches a molten state. Subsequently, the liquid steel is poured into molds to form billets, which are long rectangular blocks of steel.

Once the billets are formed, they undergo the next phase—rolling. In a steel tee factory, the billets are heated and passed through a series of rollers to create the desired cross-section. This process may involve hot rolling, where the steel is worked at high temperatures, or cold rolling, depending on the specifications. Hot rolling allows for greater flexibility in achieving the desired dimensions, while cold rolling is often used to enhance the surface finish and dimensional accuracy.

steel tee factory

After rolling, the steel tees are cut to length and subjected to various treatments to enhance their mechanical properties. These treatments may include heat treatment, which alters the microstructure of the steel, increasing its strength and toughness. In addition, surfaces may be treated with coatings or finishes to improve corrosion resistance, thereby extending the life of the product in various environmental conditions.

Quality Control and Compliance

An essential aspect of any steel tee factory is adhering to stringent quality control measures. Each batch of steel tees is subjected to rigorous testing to ensure they meet industry standards and specifications. These tests may include tensile strength tests, impact tests, and dimensional inspections. Compliance with national and international standards, such as those set by ASTM or ISO, is critical for ensuring that the products are safe and reliable for use in construction and manufacturing applications.

Environmental Responsibility

In today’s industrial landscape, sustainability and environmental responsibility are paramount. Steel tee factories are increasingly adopting eco-friendly practices, including energy-efficient manufacturing processes and the use of recycled materials. Innovations in technology, such as electric arc furnaces powered by renewable energy sources, significantly reduce the carbon footprint of steel production.

Conclusion

The steel tee factory represents a convergence of traditional manufacturing techniques and modern innovations. Its role in producing critical structural components cannot be overstated, as it supports a wide array of construction and industrial projects. By focusing on quality, compliance, and sustainability, steel tee factories are not only ensuring the strength and longevity of the structures they help build but also contributing to a more environmentally sustainable future. As industries continue to evolve, the demand for high-quality, reliable steel products will remain a cornerstone of modern development, making the steel tee factory an indispensable part of the industrial ecosystem.

-

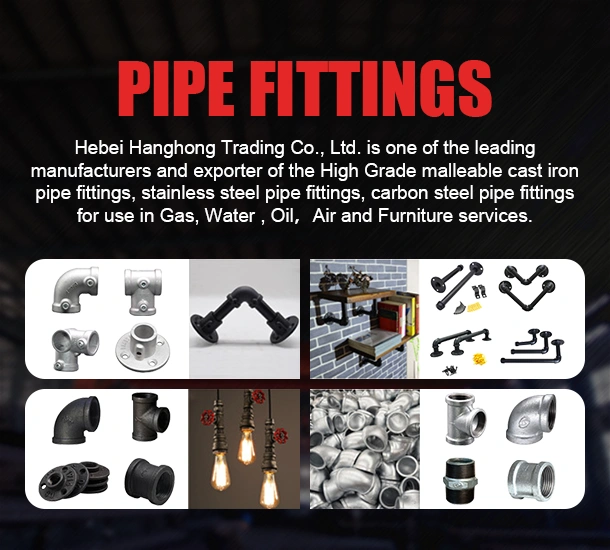

Malleable Galvanized Iron Pipe Fittings & Key Clamps - Durable

NewsAug.12,2025

-

Industrial Steampunk Swing Towel Rail - 3-Bar Pipe Design

NewsAug.11,2025

-

1" Black Malleable Iron 4-Way Cross Pipe Plumbing Fitting

NewsAug.10,2025

-

1/2"-1" Malleable Iron Fittings for DIY Metal Pipe Brackets

NewsAug.09,2025

-

3/4 1/2 Inch Malleable Iron Floor Wall Flange - Industrial Decor

NewsAug.08,2025

-

1/2" DN15 Cast Iron Pitting Floor Flange - Industrial Pipe Mount

NewsAug.07,2025