-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

Dec . 01, 2024 21:50 Back to list

Three Methods for Manufacturing Cast Iron Pipe Fittings in a Factory Setting

The Production and Benefits of Elbow Fittings in Cast Iron Pipe Manufacturing

In the world of plumbing and piping systems, the importance of elbows cannot be understated. These fittings play a crucial role in guiding water or other fluids through intricate plumbing networks, making them essential components in both residential and industrial applications. Factory-produced cast iron pipe fittings, especially elbow fittings, are renowned for their durability, strength, and resistance to various environmental factors. This article explores three primary ways that factories produce elbow fittings from cast iron and their manifold benefits.

1. Casting Process

One of the most traditional and widely used methods for producing cast iron elbow fittings is through the casting process. This begins with heating iron to a molten state, which is then poured into molds shaped like the desired elbow fittings. The molds can vary in complexity; some may be simple two-piece molds, while others might involve intricate designs to ensure a perfect fit.

The casting method allows manufacturers to produce a large quantity of fittings simultaneously, making it cost-effective and time-efficient. Once the molten iron cools and solidifies, the molds are removed, and the elbow fittings are subjected to further finishing processes. This could include grinding, machining, and coating for added corrosion resistance. Notably, cast iron elbow fittings are highly favored in industries where high pressures, temperatures, and demands for longevity are inherent.

2. Ductile Iron Technology

As technology in manufacturing has evolved, so has the composition and methodology of producing cast iron elbow fittings. Ductile iron, known for its enhanced tensile strength and ductility compared to traditional cast iron, is becoming increasingly popular. Factories employ a specialized process that involves adding a small percentage of magnesium to the molten iron. This alters the microstructure of the iron, resulting in a more flexible yet strong material.

The production of ductile iron elbow fittings uses similar casting techniques but can also incorporate advanced technologies such as precision casting. This method enables the production of complex and fine geometric features that meet specific engineering requirements. The resulting elbows not only have higher load-bearing capacities but also offer better resistance against impacts, making them ideal for utility and construction applications where reliability is crucial.

3. Automated Production Lines

With advancements in automation and robotics, many factories have turned to automated production lines for manufacturing elbow fittings. These automated systems streamline the entire process, from melting iron to molding to finishing. Incorporating Computer Numerical Control (CNC) technology allows for precise dimensions and tolerances, which ensures a high level of quality control.

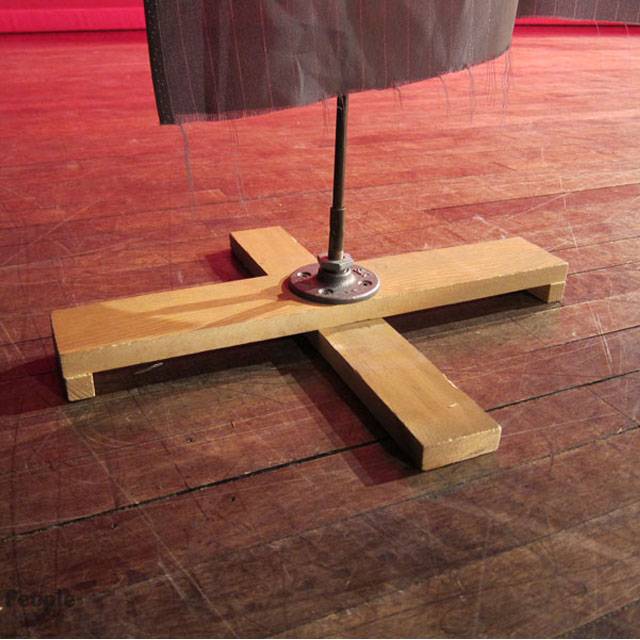

elbow 3 ways cast iron pipe fittings factory

Automation reduces human error and increases efficiency. It allows factories to produce elbow fittings at a faster rate while maintaining consistently high quality. Furthermore, automated processes can minimize waste and optimize raw material usage, contributing to sustainable practices in manufacturing. The result is a reliable supply of elbow fittings that meet the demanding standards of today’s construction and plumbing industries.

Benefits of Cast Iron Elbow Fittings

The benefits of cast iron elbow fittings go beyond their production methods

. Here are some of the key advantages they offer- Durability Cast iron is well-known for its exceptional durability and lifespan, making it ideal for challenging environments where other materials might corrode or degrade.

- Fire Resistance Cast iron has inherent fire-resistant properties, which makes it suitable for various applications, including fire protection systems.

- Cost-Effectiveness While the initial investment in cast iron fittings may be higher compared to other materials, the long-term savings in maintenance and replacement make it a financially prudent choice.

- Noise Reduction The density of cast iron absorbs sound effectively, making cast iron elbow fittings an excellent option for applications where noise reduction is a priority.

- Versatility These fittings can be used in a wide range of applications, from residential plumbing to large-scale industrial projects.

In conclusion, the production of cast iron elbow fittings through casting, ductile iron technology, and automated methods showcases the versatility and durability of these essential plumbing components. As the demand for reliable and robust piping solutions continues to grow, so too will the innovative techniques used to manufacture them. Cast iron elbow fittings not only provide practical solutions but also contribute to the sustainability and efficiency of modern plumbing systems.

-

1/2" DN15 Cast Iron Pitting Floor Flange - Industrial Pipe Mount

NewsAug.07,2025

-

Durable 3/4" Malleable Iron Floor Flange - 3-Hole

NewsAug.06,2025

-

In Stock: 1/2" & 3/4" Galvanized Malleable Iron Floor Flanges

NewsAug.04,2025

-

Premium Black & Galvanized Key Clamp Fittings for Furniture Joints | Durable

NewsAug.03,2025

-

Wholesale China Malleable Cast Iron Decorative Floor Flanges

NewsAug.02,2025

-

3/4" Reinforced Bronze Flange Iron Pipe Floor Fitting | Threaded

NewsAug.01,2025