-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

វិច្ឆិកា . 27, 2024 00:52 Back to list

Nipple and Pipe Fitting Manufacturing Facilities Overview and Insights

The Importance of Nipple and Fitting Pipe Factories in Modern Industry

In the landscape of modern manufacturing, nipple and fitting pipe factories play a pivotal role in ensuring seamless operations across various industries. From construction to plumbing, automotive to aerospace, these factories provide essential components that facilitate the flow of fluids and gases in various systems. Understanding the significance of these factories, their processes, and their contributions to the industry can provide a deeper appreciation for the intricate world of manufacturing.

What Are Nipples and Fittings?

Nipples and fittings are crucial components in piping systems. A nipple is typically a short piece of pipe with threads on both ends, allowing it to connect two other fittings or pipes. Fittings, on the other hand, are used to join pipes, change the direction of flow, or allow connections to different pipe sizes. Together, these two components form the backbone of plumbing and piping systems, ensuring that water, gas, and other substances flow efficiently from one point to another.

The Manufacturing Process

The production of nipples and fittings involves several critical steps. Factories utilize advanced machinery and technology to manufacture these components from various materials, including stainless steel, brass, and PVC. The process begins with the selection of high-quality raw materials, which are then subjected to processes like cutting, threading, and molding.

Quality control is paramount in these factories. Rigorous testing ensures that each product meets industry standards for durability and performance. This includes pressure testing to check for leaks, as well as inspections for dimensional accuracy. By maintaining high-quality standards, factories can prevent costly failures in the field and enhance the safety of the systems that rely on their products.

Sustainability and Innovation

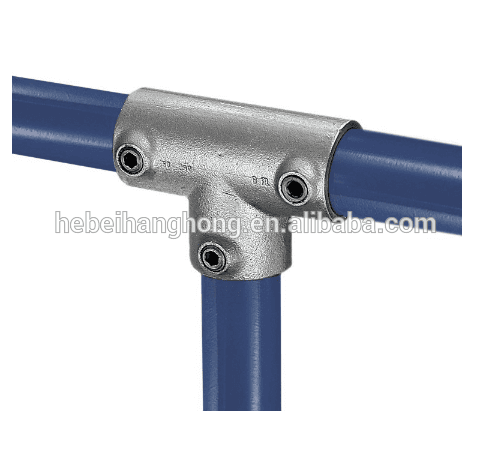

nipple fitting pipe factories

As environmental concerns grow, nipple and fitting pipe factories are also adapting to meet sustainability goals. Many manufacturers are now focusing on producing components with recyclable materials or using eco-friendly manufacturing processes. Innovation in design and materials is helping to reduce waste and improve the efficiency of piping systems, contributing to a more sustainable future.

Moreover, advancements in manufacturing technology, such as automation and robotics, are streamlining production processes. These innovations not only reduce labor costs but also improve precision and reduce variability in product quality. As the industry evolves, manufacturers that embrace new technologies will likely stay competitive in a rapidly changing market.

Market Trends and Challenges

The demand for nipple and fitting pipe components shows no signs of slowing down. With growing urbanization and infrastructure development, there is an increasing need for reliable and efficient piping systems. However, challenges such as fluctuating raw material prices, trade tariffs, and supply chain disruptions can pose risks to manufacturers. To navigate these issues, companies are increasingly turning to strategic partnerships and diversification of their supply chains.

Additionally, as industries strive for digital transformation, many factories are implementing smart manufacturing practices. This includes data analytics for predictive maintenance, which helps reduce downtime and improve operational efficiency. Factories that invest in these technologies will not only enhance their productivity but will also be better positioned to meet the demands of a modern marketplace.

Conclusion

Nipple and fitting pipe factories are indispensable to the functioning of various industries. From ensuring the safe transport of essential resources to contributing to sustainability efforts, these factories are at the forefront of manufacturing innovation. As the demand for high-quality piping components continues to grow, the factories that prioritize quality, sustainability, and technological advancement will thrive in an increasingly competitive landscape. With their vital contributions, these factories are shaping the future of industrial manufacturing and ensuring the efficient operation of systems that we often take for granted.

-

Durable 2" Black Malleable Iron Pipe & 3/4" Threaded Fittings

NewsAug.13,2025

-

Malleable Galvanized Iron Pipe Fittings & Key Clamps - Durable

NewsAug.12,2025

-

Industrial Steampunk Swing Towel Rail - 3-Bar Pipe Design

NewsAug.11,2025

-

1" Black Malleable Iron 4-Way Cross Pipe Plumbing Fitting

NewsAug.10,2025

-

1/2"-1" Malleable Iron Fittings for DIY Metal Pipe Brackets

NewsAug.09,2025

-

3/4 1/2 Inch Malleable Iron Floor Wall Flange - Industrial Decor

NewsAug.08,2025