-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

ធ្នូ . 12, 2024 11:04 Back to list

hydraulic nipple manufacturers

Understanding Hydraulic Nipple Manufacturers An Overview

Hydraulic nipples are essential components used in hydraulic systems to connect hoses and pipes, allowing fluid to be transported efficiently and safely. Their design, quality, and material composition are critical for the functionality and safety of hydraulic machinery. This article delves into the importance of hydraulic nipple manufacturers, the factors that determine their quality, and how to choose the right manufacturer for your needs.

The Role of Hydraulic Nipples

Hydraulic nipples serve as connectors in hydraulic systems, playing a vital role in maintaining fluid integrity. They are typically threaded on both ends, allowing them to easily connect to pipes or hoses. These components are commonly found in various applications, ranging from industrial machinery to automotive systems. The primary function of hydraulic nipples is to facilitate the transmission of hydraulic fluids, which can be under high pressure. Therefore, the quality of these components directly impacts system performance and safety.

Factors Influencing Quality

When evaluating hydraulic nipple manufacturers, several crucial factors come into play

1. Material Composition The material used in manufacturing hydraulic nipples significantly affects their durability and resistance to wear and tear. Common materials include steel, stainless steel, brass, and aluminum. Each material has its own advantages; for instance, stainless steel offers excellent corrosion resistance, while aluminum is lightweight and offers good strength.

2. Manufacturing Processes The techniques employed in manufacturing can influence the final product's quality. Advanced processes such as CNC machining, forging, and casting ensure precision and reliability. Manufacturers who invest in modern technology and equipment are more likely to produce high-quality components.

3. Standards and Certifications Reputable manufacturers often adhere to industry standards and possess relevant certifications, such as ISO 9001. These certifications guarantee that the company follows stringent quality control measures throughout the manufacturing process. It is advisable to choose manufacturers that prioritize quality assurance to ensure the components meet the required specifications.

4. Customization Options Different hydraulic systems may require specific dimensions, thread types, and pressure ratings. A versatile manufacturer that offers customization options can better meet unique project requirements. This flexibility is crucial, especially for industries that demand specific configurations for optimal performance.

hydraulic nipple manufacturers

5. Research and Development Companies that invest in R&D are likely to produce innovative and improved products. This can lead to better-performing hydraulic nipples that enhance system efficiency and reliability. Staying updated with technological advancements distinguishes competent manufacturers from the rest.

Choosing the Right Manufacturer

Selecting the right hydraulic nipple manufacturer is a critical decision that can influence the overall performance of your hydraulic systems. Here are some steps to guide your choice

1. Research Start by researching potential manufacturers. Look for reviews, testimonials, and case studies to assess their reputation. Online platforms and industry forums can provide valuable insights into customer experiences.

2. Request Quotes Contact multiple manufacturers to compare pricing, delivery times, and product options. This will help you gauge the market and identify competitive pricing.

3. Evaluate Customer Service A manufacturer's responsiveness and willingness to assist can be indicative of their overall service quality. Quick and effective communication can make a significant difference in resolving issues or inquiries.

4. Visit the Facility If possible, visiting the manufacturing facility can provide first-hand insights into their processes, quality control measures, and overall operation. It also gives you an opportunity to meet with engineers and assess their expertise.

5. Look for Long-term Partnerships Ideally, you want to partner with a manufacturer that can support your needs as they grow. Establishing a long-term relationship can lead to better pricing, availability, and collaboration on future projects.

In conclusion, hydraulic nipple manufacturers play a crucial role in the efficiency and reliability of hydraulic systems. Understanding the factors that influence product quality, along with thorough research and evaluation, will enable businesses to make informed decisions when selecting a manufacturer. Ultimately, investing in high-quality hydraulic nipples contributes to the safety and performance of hydraulic machinery, ensuring smooth operations in various industries.

-

Key Clamp Fitting 90 Degree Three Socket Tee – Durable & Easy Install

NewsJul.25,2025

-

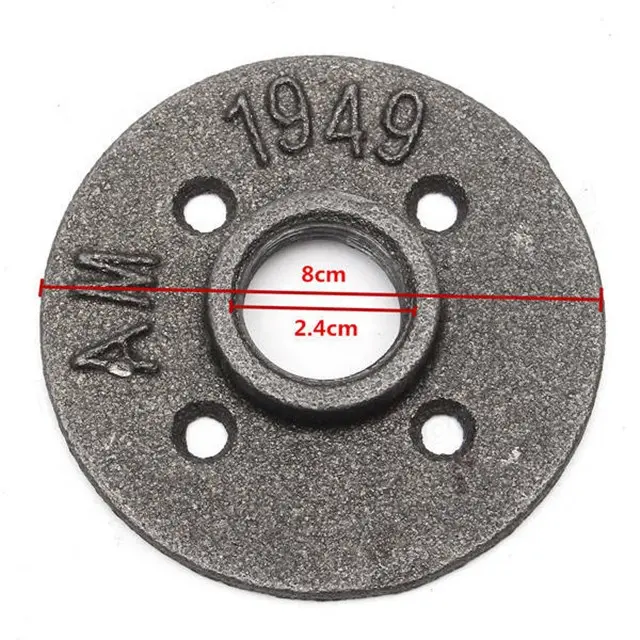

The Old Retro Dinette Antique Floor Flange for Furniture - Vintage Style Support

NewsJul.24,2025

-

3/4 Inch Reinforced Bronze Flange Iron Pipe Floor Fitting Plumbing Threaded - Durable & Corrosion Resistant

NewsJul.23,2025

-

Malleable Iron Tee Pipe Fitting Equal Reducing 3-Way Threaded Tee

NewsJul.22,2025

-

Durable 3/4" Black Cast Iron Floor Flange & Galvanized Pipe Fitting

NewsJul.22,2025

-

Premium NPT Threaded Fittings Hot Sell | Trusted Alibaba Assessed Supplier

NewsJul.21,2025