-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

វិច្ឆិកា . 08, 2024 17:09 Back to list

galvanized malleable iron manufacturers

The Importance of Galvanized Malleable Iron in Modern Manufacturing

Galvanized malleable iron has become an essential material in various industries due to its unique properties and versatility. With manufacturers looking for durable and reliable materials, galvanized malleable iron stands out as an attractive option for many applications. This article will explore the significance of galvanized malleable iron, its manufacturing process, and its applications across different sectors.

What is Galvanized Malleable Iron?

Galvanized malleable iron is iron that has undergone a process of galvanization, which involves coating it with a layer of zinc to prevent rust and corrosion. The malleable form of iron is produced through the controlled heat treatment of cast iron, allowing it to be shaped and molded without becoming brittle. The combination of malleability and galvanization provides a superior material that can withstand various environmental stressors.

Manufacturing Process

The manufacturing of galvanized malleable iron typically begins with the production of white cast iron, which is then subjected to a heat treatment process called annealing. This treatment transforms the hard and brittle cast iron into a softer, more ductile form. Once the malleable iron is produced, it undergoes a galvanization process where it is dipped in molten zinc or subjected to a hot-dip galvanization process. This coating forms a protective barrier that prevents the iron from corroding, enhancing its longevity and durability in diverse applications.

Manufacturers specializing in galvanized malleable iron often ensure that their processes adhere to industry standards and practices, improving product reliability. Innovations in production technology and quality control have led to improvements in the properties of galvanized malleable iron, making it highly sought after in various fields.

Applications of Galvanized Malleable Iron

Galvanized malleable iron is widely used in numerous applications due to its strength, durability, and resistance to corrosion. Some of the most common applications include

1. Piping and Fittings The plumbing industry extensively uses galvanized malleable iron for pipes and fittings, providing a cost-effective solution for water and gas transportation. The corrosion resistance of galvanized iron ensures longevity in underground and above-ground applications.

2. Structural Components Galvanized malleable iron is also employed in building and construction as a material for brackets, hangers, and other structural components. Its strength makes it ideal for supporting loads and enhancing the stability of construction projects.

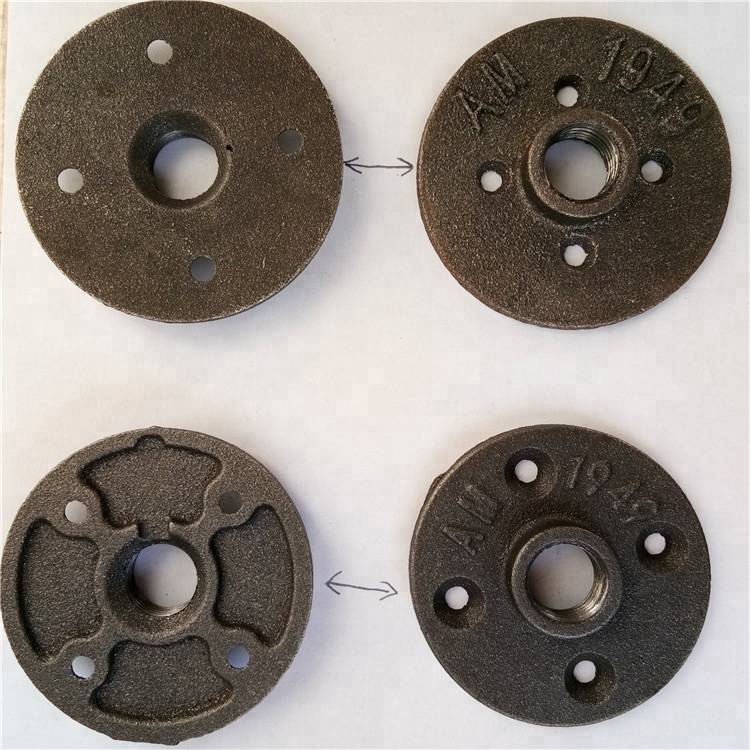

galvanized malleable iron manufacturers

3. Automotive Parts The automotive industry utilizes galvanized malleable iron for various components that require strength and resistance to harsh environmental conditions. Components such as brackets, fittings, and suspensions benefit from the properties of this material.

4. Agricultural Equipment Farmers and agricultural workers often rely on galvanized malleable iron for tools, machinery, and structural components within the agricultural sector. The durability of the material ensures it can withstand outdoor conditions and heavy usage.

5. Electrical Applications In the electrical industry, galvanized malleable iron is used for cable trays, junction boxes, and fittings that need to resist weathering and provide ample protection for electrical systems.

Advantages of Galvanized Malleable Iron

The advantages of using galvanized malleable iron extend beyond its applications. Some key benefits include

- Corrosion Resistance The zinc coating forms a protective layer that significantly reduces the risk of rust and corrosion, making it suitable for outdoor and moisture-prone environments.

- Cost-Effectiveness While initially more expensive than plain malleable iron, its long service life and low maintenance requirements make galvanized malleable iron a more cost-effective choice in the long run.

- Strength and Durability Malleable iron is known for its excellent tensile strength and ductility, allowing it to endure substantial loads and stresses without cracking.

- Ease of Fabrication Manufacturers can easily fabricate galvanized malleable iron into various shapes and sizes, accommodating the specific needs of different industries.

Conclusion

In conclusion, galvanized malleable iron manufacturers play a crucial role in providing high-quality materials that meet the demands of various industries. Its unique combination of strength, corrosion resistance, and flexibility makes it an indispensable material in applications ranging from plumbing to automotive parts. As industries continue to evolve, the role of galvanized malleable iron in construction, agriculture, and manufacturing will only become more significant, driving innovation and efficiency in production processes. With ongoing advancements in manufacturing technology, the future of galvanized malleable iron looks promising, setting new standards for quality and performance.

-

4X 3/4 Malleable Iron Pipe Fittings Floor Flange 3/4" Threaded BSP Wall Mount

NewsMar.07,2025

-

Galvanized 24yy 3/4"flange key clamp used for 26.9mm pipe

NewsMar.07,2025

-

3/4inch malleable cast iron design plumbing pipe rustic industrial pipe shelf

NewsMar.07,2025

-

3/4'' black iron floor flange for plumbing pipe table

NewsMar.07,2025

-

Malleable Iron Pipe Floor Threaded Fitting Black Flange

NewsMar.07,2025

-

china brass pipe fittings

NewsMar.07,2025