-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

ធ្នូ . 25, 2024 15:14 Back to list

China Long Nipple Fittings for Various Plumbing Applications and Needs

Understanding China Long Nipple Fittings A Comprehensive Overview

In the realm of plumbing and piping systems, various fittings play a crucial role in establishing connections that ensure fluid flow and system integrity. One such vital component is the long nipple fitting. Known for its versatility and functionality, long nipple fittings are predominantly manufactured in China, a country renowned for its extensive industrial capacity and cost-effective production methods. This article delves into the features, applications, and advantages of China long nipple fittings, shedding light on why they are a preferred choice for many industries.

What is a Long Nipple Fitting?

A long nipple fitting is a short pipe section that is threaded on both ends. It is used to connect two other fittings, valves, or equipment that are not closely adjacent to each other. By extending the distance between components, long nipples help achieve the desired alignment and spacing in piping layouts. These fittings come in various lengths and diameters to accommodate different installation requirements.

Material Composition

China long nipple fittings are typically made from a variety of materials, including stainless steel, brass, PVC, and carbon steel. The choice of material largely depends on the intended application. For instance, stainless steel nipples are favored in high-pressure environments and corrosive settings due to their durability and resistance to oxidation. On the other hand, PVC nipples are popular in residential plumbing and irrigation systems because of their lightweight and non-corrosive properties.

Manufacturing Process

The production of long nipple fittings in China involves several stages. Firstly, raw materials are sourced and inspected for quality. Manufacturing processes such as molding, machining, and machining take place next, followed by threading the ends to ensure a secure fit with other components. Strict quality control measures are adopted to ensure that each nipple fitting meets industry standards and specifications. This commitment to quality is one of the reasons why Chinese manufacturers are trusted globally for piping solutions.

Applications of Long Nipple Fittings

Long nipple fittings are widely utilized across several industries due to their adaptability and ease of installation. Some common applications include

1. Plumbing Used in residential and commercial plumbing systems to extend pipe lengths and connect various fixtures. 2. HVAC In heating, ventilation, and air conditioning systems, long nipples facilitate the connection of ductwork and piping components, ensuring efficient airflow and temperature control.

china long nipple fitting

4. Oil and Gas In the oil and gas sector, these fittings are employed in pipelines and extraction equipment, where reliability and adherence to safety standards are paramount.

5. Agriculture Irrigation systems often utilize long nipple fittings to connect various water supply lines, ensuring optimal distribution of water to crops.

Advantages of Choosing China Long Nipple Fittings

Opting for long nipple fittings from China presents several notable benefits

1. Cost-Effectiveness Chinese manufacturers offer competitive pricing, which is advantageous for large-scale projects seeking to manage budgets effectively.

2. Quality Assurance Many Chinese manufacturers adhere to international quality standards, providing certification that guarantees product reliability and performance.

3. Versatility With a wide range of sizes and materials available, long nipple fittings can be customized to meet specific project needs.

4. Quick Turnaround The advanced manufacturing capabilities in China allow for rapid production and delivery, ensuring that projects stay on schedule.

5. Global Availability With many exporters established worldwide, access to China-made long nipple fittings is easier than ever, supporting international construction and maintenance efforts.

Conclusion

In conclusion, China long nipple fittings are indispensable in various piping applications across multiple industries. Their adaptability, combined with the cost, quality, and efficiency of Chinese manufacturing, makes them an optimal choice for engineers, plumbers, and project managers alike. Understanding the intricacies of these fittings enhances decision-making when it comes to system design and implementation, ultimately leading to more effective and reliable fluid transport solutions. As the demand for such fittings continues to grow, China's role as a leading manufacturer remains significant in the global marketplace.

-

Black Malleable Cast Iron Floor Flange 1/2" BSPT, 3-Hole

NewsAug.22,2025

-

3/4 inch Black Finish Pipe Nipple for Home Decor & DIY

NewsAug.21,2025

-

3/4" Black Malleable Iron Floor Flange - Durable Pipe Fittings

NewsAug.19,2025

-

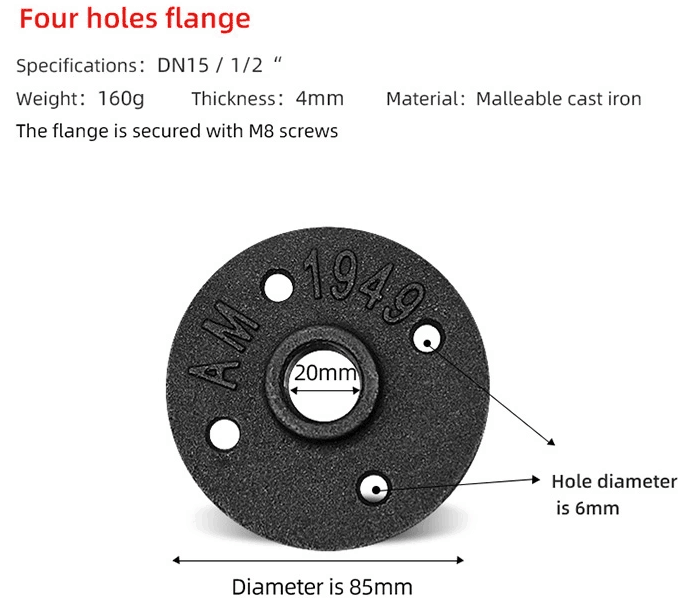

Durable DN15 1/2" Malleable Iron Threaded Floor Flange

NewsAug.18,2025

-

1/2" Malleable Iron Pipe Fittings for Furniture & Plumbing

NewsAug.17,2025

-

Urban 3/4" Floor Flange for DIY RH Inspired Shelving

NewsAug.16,2025