-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

ნოე . 10, 2024 10:58 Back to list

Factory Production of Galvanized Steel Plugs for Cast Iron Hook Applications

The Integration of Galvanized Steel Plugs in Cast Iron Hook Manufacturing

In the world of industrial manufacturing, the combination of materials often leads to enhanced product performance. One such interesting intersection is the use of galvanized steel plugs in cast iron hooks. This synergy not only improves the durability of the hooks but also enhances their overall functionality in various applications.

Understanding Cast Iron and Galvanized Steel

Cast iron has long been renowned for its excellent castability, wear resistance, and high compressive strength. It is a preferred material in many heavy-duty applications, from kitchen cookware to construction hardware. However, cast iron can be somewhat brittle, which may lead to failure under certain stress conditions. Therefore, ensuring that the design incorporates robust features is crucial.

Galvanized steel, on the other hand, is steel that has been coated in zinc to prevent corrosion. This protective layer is critical for applications in environments exposed to moisture and harsh chemicals. The galvanization process not only provides a barrier against corrosion but also enhances the aesthetic appeal of the steel surface, making it more durable and reflective.

The Role of Galvanized Steel Plugs

In the context of cast iron hooks, galvanized steel plugs serve multiple functions. Firstly, they can be used to reinforce the hook, providing additional strength and support where needed. This is particularly important in hooks that are expected to bear significant loads or are used in high-stress environments.

Additionally, the use of galvanized steel plugs can improve the overall service life of cast iron hooks. The zinc coating protects the exposed areas of the hook from rust and corrosion, leading to a longer-lasting product that requires minimal maintenance. This is particularly beneficial in outdoor or marine applications where environmental factors can cause rapid degradation of materials.

hook in cast iron with galvanized steel plug factory

Manufacturing Process

The integration of galvanized steel plugs into cast iron hooks involves a detailed manufacturing process. Initially, the cast iron hook is fabricated through molding and casting techniques specific to the desired shape and size. Once the cast iron has cooled and solidified, engineers place pre-manufactured galvanized steel plugs into specific sections of the hook.

These plugs are precision-engineered to fit snugly within the designated holes or recesses in the hook. After positioning, the plugs are often secured through welding, pressing, or fastening techniques. This step is critical to ensure that there is no movement or slippage during operation. Depending on the application, additional treatments such as powder coating for extra corrosion resistance may also be applied.

Applications and Benefits

The resulting cast iron hooks with galvanized steel plugs find applications in various fields, including construction, shipping, and even culinary tools. For instance, a heavy-duty cast iron hook with a galvanized steel plug can withstand the rigors of lifting and holding heavy materials without compromising its integrity.

Another benefit of this combination is its cost-effectiveness. By extending the lifespan of the hooks and minimizing corrosion-related failures, companies can save significantly on replacement costs and reduce downtime associated with equipment failure.

Conclusion

In summary, the use of galvanized steel plugs in the manufacturing of cast iron hooks represents a notable advancement in industrial design. This combination not only enhances the strength and durability of the hooks but also significantly improves their resistance to environmental wear and tear. As industries continue to demand higher performance and longevity from their tools, the integration of these materials will likely become more prevalent, showcasing innovation in manufacturing that meets the needs of modern applications.

-

Heavy Duty 3/4" Industrial Pipe 'T' Shelf Brackets - Dark Grey Iron

NewsAug.27,2025

-

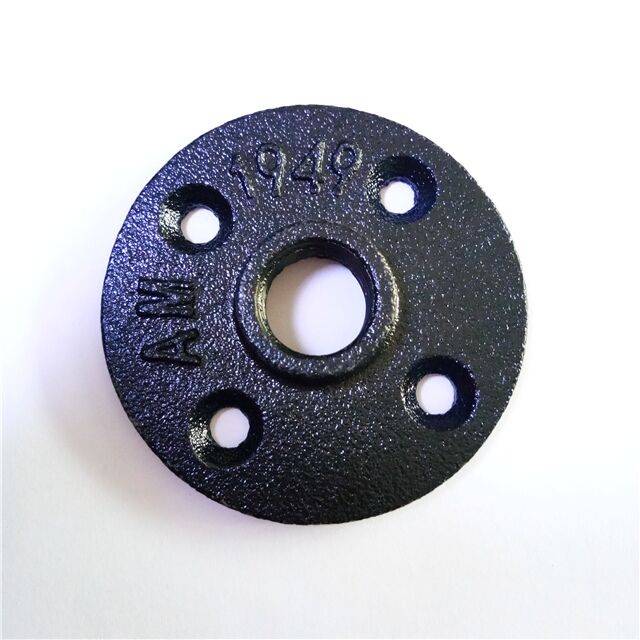

Black Floor Flange 1/2 for Furniture | Industrial Pipe Decor DIY

NewsAug.26,2025

-

Durable 1/2" 3/4" 1" Iron Threaded Floor Flange Wall Mount Pipe Fitting

NewsAug.25,2025

-

Black Malleable Cast Iron Floor Flange 1/2" BSPT, 3-Hole

NewsAug.22,2025

-

3/4 inch Black Finish Pipe Nipple for Home Decor & DIY

NewsAug.21,2025

-

3/4" Black Malleable Iron Floor Flange - Durable Pipe Fittings

NewsAug.19,2025