-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

nov . 27, 2024 10:57 Back to list

Pricing Guide for Class 150 Flanges and Related Components

Understanding the Class 150 Flange Pricelist

Flanges play a crucial role in the construction and engineering industries, acting as connectors that join two separate parts of a piping system. Among the various types of flanges available, Class 150 flanges are particularly popular due to their widespread application in low-pressure systems. This article delves into the specifics of Class 150 flanges, focusing on the pricelist and factors influencing costs.

What Are Class 150 Flanges?

Class 150 flanges are designed to handle pressures of up to 150 psi (pounds per square inch). They are commonly made from materials like carbon steel, stainless steel, and other alloys. The nominal size for these flanges usually ranges from ½ inch to 24 inches in diameter, with industry standards such as ASME (American Society of Mechanical Engineers) governing their specifications.

Class 150 flanges are widely used in various applications, including water supply systems, chemical processing, and HVAC installations. Their versatility and reliability have made them a staple in many industrial processes.

Factors Affecting the Price of Class 150 Flanges

Understanding the various factors that influence the pricing of Class 150 flanges can help buyers make informed decisions. Here are some of the primary factors

The choice of material significantly affects costs. For instance, carbon steel flanges tend to be more affordable than stainless steel ones. Each material has its own advantages stainless steel offers better corrosion resistance but comes at a higher price point. Buyers should consider the application requirements when selecting the type of flange, as the material's properties can impact not just the price but also the longevity and performance of the flange.

2. Size and Thickness

class 150 flange pricelist

Flanges come in a range of sizes and thicknesses, tailored to different applications. Larger and thicker flanges require more material, which increases the cost. Additionally, certain applications may necessitate custom sizes that can further drive up expenses. Understanding the specific needs of your project is crucial to selecting flanges that are both cost-effective and suitable for the intended use.

3. Manufacturing Process

The production methods used to create Class 150 flanges are important to consider as well. There are forged, cast, and fabricated flanges, each with distinct manufacturing processes that affect pricing. Forged flanges are typically stronger and can be more expensive due to the intensive manufacturing process involved. Conversely, cast flanges, while generally less expensive, may not provide the same level of strength and reliability.

4. Quantity Ordered

Bulk purchasing often results in discounts, so the quantity of flanges ordered can impact the individual price. Suppliers typically offer tiered pricing, which encourages companies to buy larger quantities for better cost efficiency. This can be beneficial for contractors and industrial firms that require large amounts of flanges for ongoing projects.

5. Supplier and Market Trends

Market demand and supplier availability can fluctuate, influencing flange prices. Buying from reputable manufacturers or suppliers may come with a higher initial cost but can ensure better quality and reliability. Keeping an eye on market trends and seeking quotes from multiple suppliers can lead to better pricing and options.

Conclusion

In summary, understanding the Class 150 flange pricelist involves recognizing the various factors that affect pricing. From material choice and manufacturing processes to quantity and market dynamics, several elements play a crucial role. When selecting Class 150 flanges, it is important for buyers to assess their specific application requirements and consult with reliable suppliers to ensure they are making informed decisions. Whether for a construction project, maintenance task, or a specialized application, finding the right flange at a reasonable price can significantly impact the overall success of the operation. By staying informed about the pricing factors, buyers can navigate the complexities of flange procurement with confidence.

-

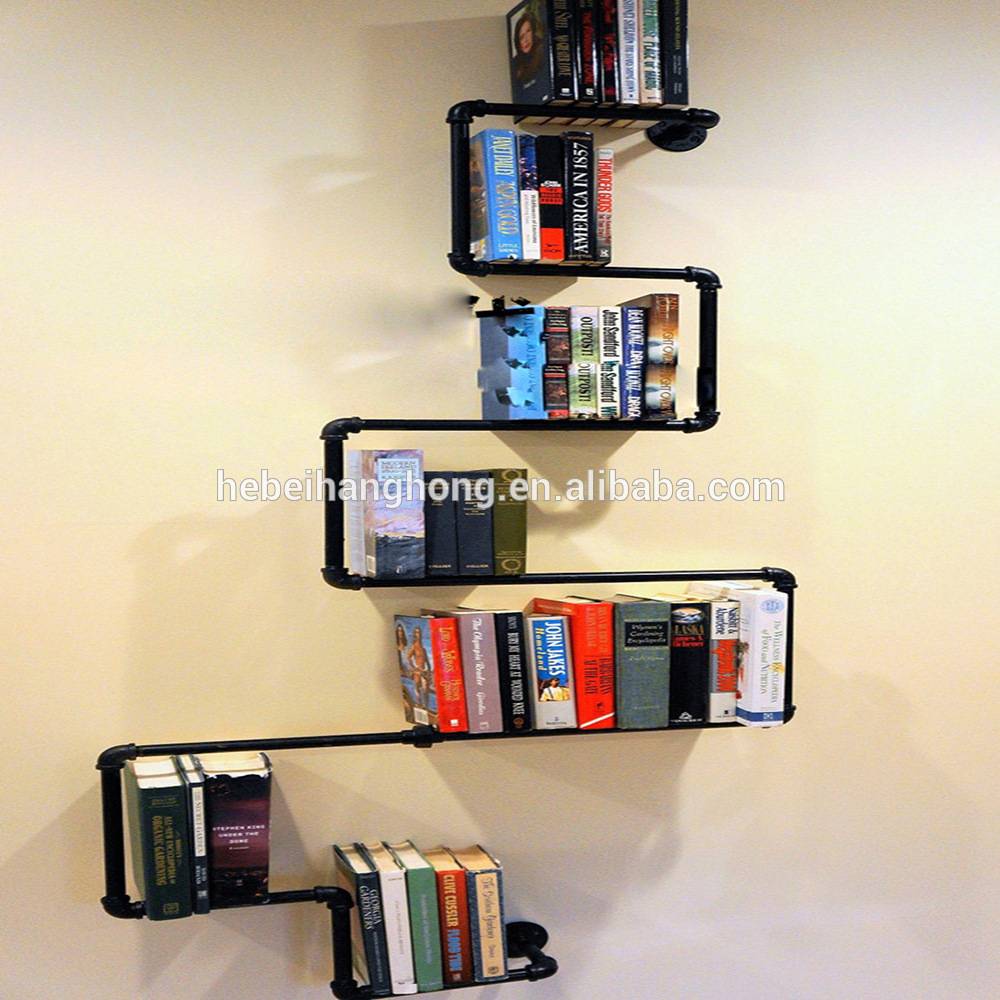

Durable 2" Black Malleable Iron Pipe & 3/4" Threaded Fittings

NewsAug.13,2025

-

Malleable Galvanized Iron Pipe Fittings & Key Clamps - Durable

NewsAug.12,2025

-

Industrial Steampunk Swing Towel Rail - 3-Bar Pipe Design

NewsAug.11,2025

-

1" Black Malleable Iron 4-Way Cross Pipe Plumbing Fitting

NewsAug.10,2025

-

1/2"-1" Malleable Iron Fittings for DIY Metal Pipe Brackets

NewsAug.09,2025

-

3/4 1/2 Inch Malleable Iron Floor Wall Flange - Industrial Decor

NewsAug.08,2025