-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

nov. . 09, 2024 15:16 Back to list

1/2 Inch Malleable Iron Pipe Fittings Production and Manufacturing Insights

Understanding 1/2 Pipe Fittings Made of Malleable Iron

In the world of plumbing and construction, the choice of materials and fittings is critical for ensuring safety, performance, and durability. One often overlooked yet essential component is the 1/2 pipe fitting made of malleable iron. This article dives into the characteristics, advantages, and applications of these fittings, as well as the manufacturing processes involved in their production.

What is Malleable Iron?

Malleable iron is a type of iron that has been treated to make it ductile and workable. Unlike cast iron, which can be brittle and prone to breaking under stress, malleable iron features a unique microstructure that allows it to be shaped and formed without cracking. The flexibility and strength of malleable iron make it an ideal choice for pipe fittings, which must withstand high pressure and temperature variations in plumbing and industrial applications.

Characteristics of 1/2 Malleable Iron Pipe Fittings

1. Durability Malleable iron fittings are known for their robustness, making them suitable for various applications, especially where high strength is required. With a tensile strength significantly higher than that of some other materials, these fittings can endure demanding conditions.

2. Corrosion Resistance Although iron can rust when exposed to moisture, many manufacturers apply coatings or finishes to enhance corrosion resistance. Options such as galvanization or powder coating can significantly extend the life of malleable iron pipe fittings, making them suitable for both indoor and outdoor use.

3. Temperature Tolerance Malleable iron can handle a wide range of temperatures, making it ideal for applications that experience significant temperature fluctuations. This quality ensures reliable performance in hot water and steam systems, as well as in refrigeration and cooling applications.

4. Versatility The 1/2 size is a common choice in various plumbing systems, including residential and industrial pipelines. Malleable iron fittings can be used in numerous configurations, such as elbows, tees, reducers, and caps, allowing for flexibility in system designs.

Applications of 1/2 Malleable Iron Pipe Fittings

These fittings find applications in a wide range of industries, including

- Plumbing Malleable iron pipe fittings are extensively used in residential plumbing systems for connecting water lines, thereby ensuring a reliable and leak-free water supply.

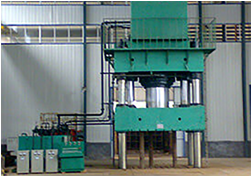

1/2 pipe fittings malleable iron factory

- Gas Lines The ability of malleable iron to withstand high pressures makes it suitable for natural gas and other gas piping systems. These fittings are indispensable in ensuring the safety and integrity of gas installations.

- Industrial Applications In manufacturing and processing facilities, malleable iron fittings are used in various fluid and gas transport systems, contributing to the overall efficiency of operations.

- HVAC Systems Heating, ventilation, and air conditioning systems greatly benefit from the use of durable and reliable pipe fittings, with malleable iron providing the necessary strength and longevity.

Manufacturing Process of Malleable Iron Fittings

The production of 1/2 malleable iron pipe fittings involves several key steps

1. Iron Casting The process begins with the melting of iron, which is then cast into molds to create the desired fittings’ shapes.

2. Heat Treatment Once the castings are cooled, they undergo heat treatment to transform their structure, enhancing mechanical properties and ductility.

3. Machining After heat treatment, the fittings may require machining to achieve precise dimensions and smooth surfaces.

4. Finishing The final steps involve applying protective coatings to improve corrosion resistance and polishing to enhance aesthetics.

5. Quality Control Rigorous testing and inspections are carried out to ensure that the fittings meet industry standards for safety and performance.

Conclusion

1/2 pipe fittings made of malleable iron are an indispensable component in modern plumbing and industrial systems. Their unique properties, including durability, temperature tolerance, and versatility, make them well-suited for various applications. As technology advances, manufacturers continue to improve the quality and performance of malleable iron fittings, ensuring that they remain a reliable choice for engineers and contractors alike. Whether for gas lines, water systems, or HVAC applications, malleable iron fittings provide the strength and reliability needed to deliver performance in demanding environments.

-

Heavy Duty 3/4" Industrial Pipe 'T' Shelf Brackets - Dark Grey Iron

NewsAug.27,2025

-

Black Floor Flange 1/2 for Furniture | Industrial Pipe Decor DIY

NewsAug.26,2025

-

Durable 1/2" 3/4" 1" Iron Threaded Floor Flange Wall Mount Pipe Fitting

NewsAug.25,2025

-

Black Malleable Cast Iron Floor Flange 1/2" BSPT, 3-Hole

NewsAug.22,2025

-

3/4 inch Black Finish Pipe Nipple for Home Decor & DIY

NewsAug.21,2025

-

3/4" Black Malleable Iron Floor Flange - Durable Pipe Fittings

NewsAug.19,2025