-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

nov . 05, 2024 04:33 Back to list

hexagon nipple factory

The Hexagon Nipple Factory A Marvel of Modern Manufacturing

In the ever-evolving realm of manufacturing, the hexagon nipple factory stands as a prime example of innovation and precision engineering. Specializing in the production of hexagonal nipples, a vital component in plumbing and gas connections, these factories play a crucial role in ensuring that our modern infrastructure functions smoothly and securely.

What Are Hexagonal Nipples?

Before delving further into the workings of a hexagon nipple factory, it’s essential to understand what hexagonal nipples are. In plumbing and gas fitting, a nipple refers to a short piece of pipe with threads on both ends, used to connect two other fittings. The hexagonal shape facilitates easy tightening and fitting into various systems, making these components indispensable in numerous applications such as residential and commercial plumbing, gas lines, and industrial systems.

The Manufacturing Process

The journey of a hexagonal nipple begins with raw materials, primarily high-grade metals such as brass, copper, or stainless steel. These materials are chosen for their durability, corrosion resistance, and ability to endure high pressure, which are critical for the reliability of the final product.

The manufacturing process typically involves several distinct stages

1. Material Preparation Raw materials are first cut and shaped into cylindrical forms using cutting machines. Precision is crucial at this stage to ensure that the dimensions match the required specifications.

2. Machining The shaped cylinders undergo machining, where they are turned on a lathe to create the threads that will connect the nipple to other fittings. This step requires intricate programming and careful supervision to ensure that the threads meet industry standards.

3. Hexagon Shaping Following the threading process, the cylindrical nipples are precisely transformed into hexagonal shapes. This is achieved using advanced CNC (Computer Numerical Control) machinery, which guarantees that each edge is evenly sized and aligned for smooth fitting.

hexagon nipple factory

4. Surface Treatment After shaping, the nipples undergo surface treatment processes such as galvanization or polishing. These treatments enhance corrosion resistance and improve the aesthetic appeal of the final product.

5. Quality Control The factory then implements rigorous quality control measures. Each batch of hexagonal nipples is tested for strength, pressure tolerance, and dimensional accuracy. Any defective pieces are discarded to maintain the high standards associated with the factory's products.

6. Packaging and Distribution Finally, once all products pass inspection, they are carefully packaged and prepared for distribution. The factory often maintains partnerships with various distributors and retailers, ensuring that their products reach customers efficiently.

The Importance of Precision

In the hexagon nipple manufacturing process, precision is paramount. A slight error in threading or dimension could lead to leaks or failures in critical systems, potentially resulting in costly repairs or hazardous situations. The reliance on CNC technology has revolutionized the precision achievable in manufacturing, allowing factories to produce thousands of high-quality components with remarkable consistency.

Innovations and Sustainability

As industries continue to evolve, the hexagon nipple factory is also embracing innovative techniques. Automation and robotics are increasingly being integrated into the production line, enhancing efficiency and reducing labor costs. Moreover, there is a growing emphasis on sustainability, with factories exploring ways to minimize waste and recycle materials. By adopting eco-friendly practices, these facilities contribute positively to the environment, aligning with global efforts for sustainable manufacturing.

Conclusion

In summary, the hexagon nipple factory is a marvel of modern engineering that plays a vital role in our everyday lives. From the precise manufacturing processes to the stringent quality controls, each aspect of production ensures that hexagonal nipples meet the highest standards required for safety and reliability. With advancements in technology and a commitment to sustainability, these factories are not just about producing components; they are integral to a future where infrastructure can thrive on the foundations of quality and ingenuity. As we look forward, the continued evolution of the hexagon nipple factory will undoubtedly leave an indelible mark on the manufacturing landscape.

-

4X 3/4 Malleable Iron Pipe Fittings Floor Flange 3/4" Threaded BSP Wall Mount

NewsMar.07,2025

-

Galvanized 24yy 3/4"flange key clamp used for 26.9mm pipe

NewsMar.07,2025

-

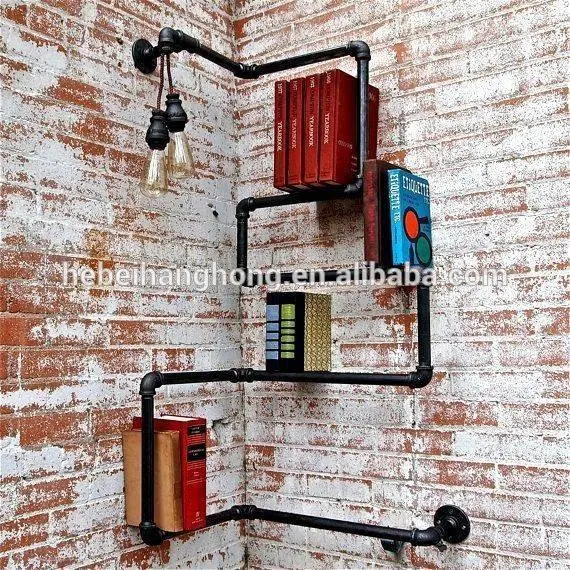

3/4inch malleable cast iron design plumbing pipe rustic industrial pipe shelf

NewsMar.07,2025

-

3/4'' black iron floor flange for plumbing pipe table

NewsMar.07,2025

-

Malleable Iron Pipe Floor Threaded Fitting Black Flange

NewsMar.07,2025

-

china brass pipe fittings

NewsMar.07,2025