-

Mail Usadmin1@hanghongtrade.com

Mail Usadmin1@hanghongtrade.com -

Call Us+8613313271100

Call Us+8613313271100 -

language

дек. . 04, 2024 22:06 Back to list

hot dip galvanized fittings factory

The Importance of Hot-Dip Galvanized Fittings A Comprehensive Guide

Hot-dip galvanization has emerged as one of the most effective methods for protecting steel from corrosion. This process, which involves coating steel with a layer of zinc, is particularly beneficial for fittings used in various construction and infrastructure applications. In this article, we will explore the significance of hot-dip galvanized fittings, their manufacturing process, advantages, and applications in multiple industries.

Understanding Hot-Dip Galvanization

The hot-dip galvanization process involves submerging steel components in molten zinc. This creates a robust bond between the zinc and the steel, forming a protective layer that prevents moisture and oxygen from reaching the underlying metal. This method not only enhances the durability of the fittings but also provides a longer lifespan compared to other protective coatings.

Advantages of Using Hot-Dip Galvanized Fittings

1. Superior Corrosion Resistance One of the primary benefits of hot-dip galvanized fittings is their exceptional resistance to corrosion. Zinc acts as a sacrificial anode, meaning that it will corrode before the steel does. This property extends the service life of fittings, making them ideal for outdoor and harsh environments.

2. Cost-Effectiveness Although the initial cost of hot-dip galvanization may be higher compared to other coatings, the long-term savings are significant. With a longer lifespan and reduced maintenance costs, hot-dip galvanized fittings offer excellent value for money.

3. Low Maintenance Requirements Once hot-dip galvanized fittings are installed, they require minimal upkeep. Unlike painted fittings which may require regular touch-ups, galvanized fittings can withstand the elements without the need for constant care.

4. Environmental Safety Galvanization is considered an environmentally friendly process. The zinc used is a natural resource, and the process generates minimal waste, making it a sustainable choice for manufacturers.

5. Aesthetic Appeal Hot-dip galvanized fittings possess a clean, uniform appearance, making them suitable for visible structural applications. The shiny surface also tends to be more resistant to staining and can maintain its appearance over time.

Manufacturing Hot-Dip Galvanized Fittings

hot dip galvanized fittings factory

The manufacturing process of hot-dip galvanized fittings begins with surface preparation. Steel components undergo cleaning through methods such as shot blasting or acid pickling to remove impurities like rust, oil, or mill scale. Once cleaned, they are dipped into molten zinc at temperatures around 450°C (840°F). The result is a durable coating that adheres firmly to the steel base.

After coating, the fittings are cooled and inspected for quality assurance. This ensures that each fitting meets industry standards for thickness and adhesion. An experienced hot-dip galvanized fittings factory employs stringent quality control measures to guarantee that their products offer maximum performance and reliability.

Applications of Hot-Dip Galvanized Fittings

Hot-dip galvanized fittings are utilized across various industries, including

1. Construction In building projects, these fittings are used in structures such as bridges, towers, and scaffolding, where longevity and strength are critical.

2. Agriculture Farmers use hot-dip galvanized fittings in fencing, grain bins, and livestock shelters due to their robust nature and resistance to outdoor conditions.

3. Utilities Water and gas companies rely on galvanized fittings for pipelines and other infrastructure where exposure to the elements is a concern.

4. Manufacturing Hot-dip galvanized components are often used in the production of manufacturing equipment and machinery parts, where resistance to wear and corrosion is paramount.

Conclusion

Hot-dip galvanized fittings represent an intersection of durability, cost-effectiveness, and environmental sustainability. Their exceptional performance in hostile environments makes them an indispensable choice for various applications across multiple industries. By choosing hot-dip galvanized fittings, industries can ensure the longevity and reliability of their infrastructure, ultimately contributing to safer and more efficient operations. Whether in construction, agriculture, or utilities, these fittings prove time and again that they are a worthwhile investment.

-

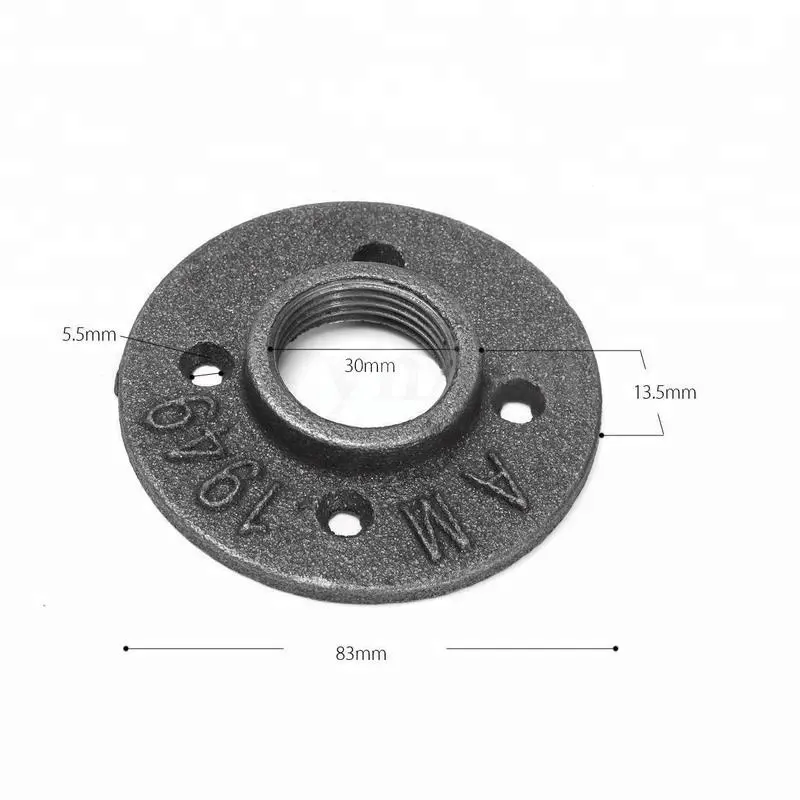

In Stock: 1/2" & 3/4" Galvanized Malleable Iron Floor Flanges

NewsAug.04,2025

-

Premium Black & Galvanized Key Clamp Fittings for Furniture Joints | Durable

NewsAug.03,2025

-

Wholesale China Malleable Cast Iron Decorative Floor Flanges

NewsAug.02,2025

-

3/4" Reinforced Bronze Flange Iron Pipe Floor Fitting | Threaded

NewsAug.01,2025

-

3/4 Inch Black Malleable Iron Floor Flange - Heavy Duty

NewsJul.31,2025

-

Premium Malleable Galvanized Cast Iron Pipe Fittings & Key Clamps

NewsJul.30,2025